The stability and longevity of concrete structures are paramount to the integrity of buildings, and understanding the causes of cracks in concrete plays a critical role in preserving their structural health. Whether it’s the hairline fissures that emerge over time or the more pronounced shrinkage cracks that quickly raise alarm, the reasons behind these imperfections are both varied and complex.

With a focus on structural damage prevention, property owners and construction professionals alike seek knowledge on the causes of cracks in concrete structures to thwart potential compromises in safety and durability. In our exploration, we will uncover the myriad factors—from material flaws to environmental stressors—that account for the causes of hairline cracks in concrete as well as the causes of shrinkage cracks in concrete, providing a foundation for remediation and future prevention.

Key Takeaways

- Identifying and addressing the various causes of cracks can significantly extend the life of concrete structures.

- Early detection of hairline and shrinkage cracks is critical for preventing more severe structural damage.

- Proper construction practices and materials selection are essential for minimizing the incidence of cracking.

- Environmental factors, including temperature changes and moisture, are significant contributors to concrete deterioration.

- Effective curing processes and understanding soil dynamics also play a vital role in maintaining concrete integrity.

- Regular monitoring and maintenance can aid in the management of existing cracks and reduce the risk of new ones developing.

Understanding Cracks in Concrete: An Overview

Concrete, a fundamental building material, is renowned for its strength and longevity. However, while it forms the backbone of modern infrastructure, it is not impervious to damage. Cracking is a common issue that can compromise the structural integrity of concrete, and understanding the underlying causes is crucial for maintaining its concrete durability.

Essential Properties of Concrete

The inherent qualities that make concrete a preferred material in construction include its high compressive strength, resistance to fire and water, flexibility in shaping, and its ability to bond with reinforcing materials to enhance structural support. Despite these impressive concrete properties, certain factors such as the mix composition, curing process, and external stresses can influence its performance over time.

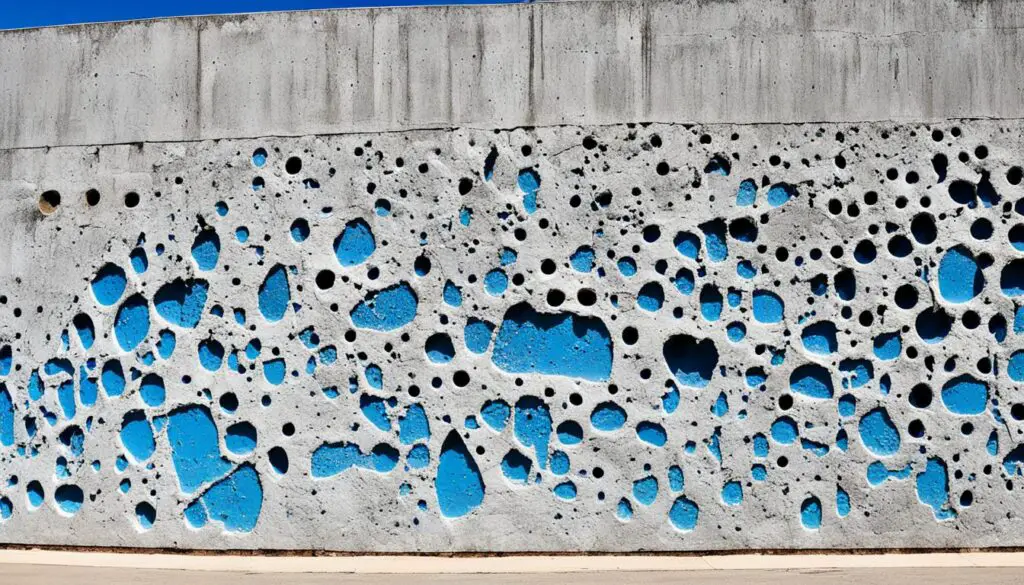

The Science Behind Concrete Deterioration

Concrete deterioration occurs due to various chemical, physical, and environmental stressors. The resulting cracks can lead to further issues such as water ingress, which accelerates damage through freeze-thaw cycles and reinforces corrosion. Such concrete deterioration ultimately affects the structural integrity of buildings, roads, bridges, and other concrete edifices.

Understanding the complex interplay between these elements is key to diagnosing and addressing the root causes of cracking, ensuring long-term concrete viability.

| Factor Contributing to Concrete Durability | Characteristic | Impact on Durability |

|---|---|---|

| Compressive Strength | Ability to withstand loads without cracking | Essential for long-standing structures under pressure |

| Water Resistance | Low permeability reduces the ingress | Prevents deterioration and reinforcing material corrosion |

| Thermal Resistance | Endures high temperatures without losing integrity | Limits expansion and contraction, reducing crack formation |

| Bonding with Reinforcements | Adheres to materials like steel to enhance tensile strength | Integral for resisting bending and shear forces |

Environmental Factors Affecting Concrete Integrity

The environmental impact on concrete is a pressing issue for construction professionals worldwide. Factors such as temperature fluctuations, moisture exposure, and the presence of chemicals in the environment significantly influence the condition and lifespan of concrete infrastructure. These elements can lead to a progressively aggressive weathering effect on concrete structures, precipitating various degrees of damage.

In regions that experience a wide range of temperatures throughout the year, the inevitable expansion and contraction of concrete can cause cracks in concrete pavements and other flatwork. Too often, these cracks provide a pathway for water and contaminants to penetrate deeper into the concrete, causing progressive deterioration from within.

Concrete is similar to living skin in regards to its reaction to the environment; it feels, breathes, expands and contracts, which greatly impacts its durability over time.

Furthermore, chemical reactions with pollutants and chemicals, such as road salts or sulfuric acids in urban settings, corrode concrete at an accelerated rate. This environment-construction chemistry not only weakens the structural integrity but also causes cracks in concrete pavements and other surfaces that are constantly exposed to harsh elements.

- Temperature variations contribute to thermal expansion and cracking

- Moisture infiltration leads to freeze-thaw cycles in colder climates

- Chemical exposure causes corrosion and increases porosity

- Solar radiation and heat can dry out and shrink concrete

To mitigate these environmental impacts, proper design considerations, selection of durable materials, and regular maintenance are paramount. The balance between practicality and environmental resilience in concrete structures is key to sustaining their integrity well into the future.

Material and Concrete Mix Issues Leading to Cracks in Concrete

The integrity and longevity of concrete structures heavily rely on a well-designed concrete mix and the quality of materials used. Flaws in the mix design or material defects are often precursors to the formation of undesirable cracks in concrete slabs. It is vital to understand how these factors can undermine a structure’s durability and what can be done to minimize risk.

Aggregate Quality and Its Impact on Concrete

Aggregates play a critical role in the structure of concrete, and their quality can greatly affect the outcome of your concrete mix design. High-quality aggregates reduce the chance of cracks in concrete slabs by providing a strong, stable framework for the cement paste to bind. Impurities or an inappropriate size distribution can compromise the integrity of the concrete and potentially lead to cracking.

The Role of Water-Cement Ratio in Concrete Durability

The water-cement ratio is a crucial component of concrete mix design that directly correlates with concrete’s durability and strength. An optimal ratio ensures the concrete mix is workable yet durable. Too much water leads to higher porosity and weaker concrete, rendering it susceptible to cracking over time.

| Concrete Component | Role in Durability | Impact on Mix Design |

|---|---|---|

| Aggregate Quality | Provides structure and compressive strength | Poor quality increases the risk of cracking |

| Water-Cement Ratio | Determines porosity and strength | Incorrect ratio can lead to premature cracking |

| Admixtures | Enhance properties such as workability | Must be carefully calibrated to avoid negative effects |

To mitigate the causes of cracks in concrete slabs, attention must be paid not only to selecting high-quality aggregates but also to calculating the appropriate water-cement ratio during the mix design phase. Achieving the right balance is key to constructing concrete slabs that stand the test of time without succumbing to the extensive cracking that plagues many structures.

Inadequate Curing and Its Consequences

The concrete curing process is an indispensable phase in construction that significantly influences the final strength and durability of concrete structures. When done correctly, curing can prevent curing-related cracking, ensuring the longevity of concrete slabs and other elements. Here, we delve into the crucial steps required for effective concrete curing and how neglecting these steps can lead to structural inadequacies, such as shrinkage cracks in concrete.

Importance of Proper Curing for Concrete Longevity

Curing is not merely a recommendation; it is a requirement for the health of concrete structures. The method involves maintaining adequate moisture, temperature, and time to allow the concrete to achieve its intended properties. When curing is inadequate, the material can become prone to rapid moisture loss leading to an incomplete hydration process. The outcome is a compromised concrete slab longevity and reduced resistance to environmental stressors.

Common Curing Mistakes and Prevention Strategies

Many of the flaws during the curing phase arise from human error and lack of knowledge. For example, premature drying due to insufficient or uneven moisture application often becomes the cause of shrinkage cracks in concrete. To circumvent such issues, consider the following strategies:

- Maintain a consistent and adequate moisture level on the concrete surface during the critical early stages of curing.

- Utilize curing compounds that form a moisture-retentive film over the surface, particularly in conditions that are not conducive to standard curing methods.

- Implement gradual drying-out periods to minimize stress within the structure, a process known as moist curing, which is vital for climates that have high evaporation rates.

By acknowledging the importance of the curing stage and applying these preventive measures, construction professionals can greatly reduce the risk of curing-related cracking and enhance the overall quality of concrete work.

causes of cracks in concrete

Concrete is often seen as a symbol of modern strength—a robust material capable of superior performance in construction. However, it can fall prey to structural deterioration, sometimes manifesting in the form of cracks. Recognizing the potential causes of cracks in concrete beams and columns is pivotal for both protection and concrete defect prevention.

Often, load-induced cracking becomes a central issue, where the weight and stress applied to concrete structures exceed their designed load-bearing capacity. In addition to the stressors of weight, environmental influences can also expedite the occurrence of fractures, thus compromising both function and form. Furthermore, the inception and propagation of cracks could be tied directly to the causes of cracks in concrete beams, where a fault in design or execution leads to unintended consequences.

“Design, materials, and execution are the three pillars of concrete stability. Neglect in any of these areas can lead to crack development, which is both a symptom and a cause of structural deterioration.”

Let’s explore further the common causes that contribute to this concrete conundrum:

- **Errors in Design**: Poorly planned design that fails to account for stress distribution and load paths.

- **Flawed Construction Practices**: Faulty construction methods, including improper placement and consolidation of concrete.

- **Insufficient Quality Controls**: Lack of rigorous quality checks at each stage of the concrete life cycle, leading to defects.

To delve deeper into the specifics, here’s a detailed table of factors causing cracks, specifically in beams and columns:

| Factor | Description | Preventive Measures |

|---|---|---|

| Design Flaws | Inadequate structural planning and over/underestimation of loads. | Use advanced design software; adhere to updated building codes. |

| Material Deficiencies | Compromises in aggregate quality and improper water-cement ratio. | Strict material selection and adherence to concrete mix guidelines. |

| Poor Workmanship | Inaccurate formwork installation, and inadequate concrete curing and finishing. | Skilled labor, proper training, and supervision. |

| Load-Induced Stress | Excessive loads lead to stress beyond the concrete’s capacity. | Regular structural assessment and load management. |

The clear identification and understanding of these causes allow for both proactive and reactive measures. More importantly, they empower stakeholders in the construction industry to uphold the structural integrity and longevity of their concrete structures, providing safe and dependable built environments.

Thermal Expansion and Contraction in Concrete Structures

Concrete structures are not immune to the shifts in temperature that accompany seasonal changes. These temperature fluctuations can significantly impact the integrity of concrete through thermal expansion and thermal contraction, leading to temperature-induced cracking. Understanding this dynamic behavior is crucial for preventing the causes of hairline cracks in concrete, which often stem from these thermal stresses.

How Temperature Fluctuations Lead to Concrete Cracking

As temperatures rise, concrete experiences thermal expansion. Conversely, cooling results in thermal contraction. This continual cycle creates stress within the concrete’s structure, as it is constrained by its rigidity and the surrounding environment. Over time, these stresses can culminate in cracks that, while initially minute, can expand and compromise the concrete’s stability.

Designing for Thermal Stresses in Concrete

To mitigate the risk of cracking from thermal stress, engineers employ design strategies that allow concrete structures to accommodate movements caused by temperature changes. These include the use of expansion joints, the selection of appropriate concrete materials, and specific structural reinforcements. Incorporating these elements can significantly reduce the susceptibility to thermal expansion in concrete and its counterpart, thermal contraction.

| Strategy | Description | Benefits |

|---|---|---|

| Expansion Joints | Spaces between slabs that allow for expansion and contraction without causing damage. | Prevents hairline and larger cracks, and maintains surface integrity. |

| Material Selection | Choosing concrete with appropriate thermal coefficients. | Reduces the extent of expansion/contraction, lowering stress on the structure. |

| Structural Design | Integrates factors such as section size and reinforcement to combat thermal stresses. | Enhances durability against temperature-induced cracking. |

Armed with this knowledge, architects and builders can better predict and prevent damages resulting from the inherent thermal expansion and contraction of concrete structures, thus ensuring their longevity and functionality.

Structural Overloading and its Implications

When it comes to the stability of concrete structures, understanding the limits is critical. Structural overloading occurs when the force applied to a building component exceeds its capacity to resist it. This can lead to load-bearing cracks, a serious concern for anyone responsible for maintaining the integrity of a concrete edifice. In the realm of construction and engineering, it is imperative to recognize the causes of cracks in concrete floors, as they often bear the brunt of excessive loads.

- Distinguishing between transient and permanent loads

- Recognizing signs of overstress in floor systems

- Implementing regular inspections to detect early indications of overload

By adhering to design specifications and load guidelines, the risks associated with overloading can be minimized. Preventative measures, such as strategic planning of load distribution and timely renovations, play a vital role in preserving the structural integrity of concrete floors.

| Factor | Safe Load Limit | Preventive Measure |

|---|---|---|

| Material Strength | Varies by concrete mix | Quality control during the mixing process |

| Design Specification | As per the engineer’s calculation | Adherence to structural design |

| Aging of Structure | Decreased over time | Regular maintenance and inspection |

To mitigate the risk of structural overloading, it’s crucial not only to understand the origin and nature of loads but also to act preemptively. Regular monitoring, combined with an awareness of the maximum safe load capacities, can stave off the development of cracks and other structural complications. While causes of cracks in concrete floors vary, proactive management is the common denominator in preserving the longevity and safety of concrete structures.

Ground Movement and Settlement Issues

As the built environment interacts with the natural landscape, soil settlement and other forms of ground movement can lead to significant structural problems. Among these are the subsidence-related cracks that mar concrete walls, indicating deeper issues beneath the surface. These phenomena are not merely cosmetic flaws but signs of potentially serious ground movement impacts.

Understanding Soil Dynamics Related to Concrete Cracking

Different soil types and conditions can lead to various responses within concrete structures. Clay-rich soils that expand and contract with moisture changes, or loosely compacted soils subject to settlement, can create undue stress on concrete walls. This movement often results in cracks and structural integrity loss. By identifying the causes of cracks in concrete walls, engineers and construction professionals can develop more resilient structures poised to withstand these shifts.

Design Considerations for Soil-Structure Interaction

Addressing the issue of ground movement begins with comprehensive site analysis and design considerations for soil-structure interaction. Strategies such as ensuring proper soil compaction, considering the use of pilings, and integrating flexible joints into the design are but a few ways to combat the challenges posed by soil dynamics. Thoughtful planning that accounts for the local geological conditions can minimize the risk of soil settlement and its adverse effects on concrete structures.

Corrosion of Reinforcement within Concrete Structures

Reinforcing steel corrosion is a significant threat to the longevity and safety of concrete structures. Understanding the early signs of corrosion-induced cracks and the subsequent steps for concrete structural rehabilitation can significantly extend the lifespan of infrastructure, particularly concrete columns which are crucial to a building’s structural integrity.

Identifying Early Signs of Reinforcement Corrosion

Monitoring for symptoms of reinforcing steel corrosion is vital for timely intervention. Typical indications include rust stains or spalling on concrete surfaces, which suggest that the steel within has started to oxidize. In advanced cases, noticeable corrosion-induced cracks can be seen, which are often wider than the hairline and appear in parallel lines directly above the rebar locations. Such damages demand immediate attention to prevent catastrophic failures.

Mitigation and Repair Options for Corroded Reinforcements

When reinforcing steel begins to corrode and compromise the structure, concrete structural rehabilitation becomes a priority. Repair options include removing the damaged concrete, treating or replacing the corroded steel, and applying a corrosion inhibitor. It is critical to address the causes of cracks in concrete columns to prevent recurrence. Here are some key strategies:

| Strategy | Method | Benefit |

|---|---|---|

| Epoxy Injection | Sealing cracks with epoxy resins | Restores structural strength and seals against water ingress |

| Cathodic Protection | Applying electrical current to slow down the corrosion process | Extends the service life of reinforcement bars |

| Corrosion Inhibitors | Use of chemicals to prevent further corrosion | Protects uncorroded areas and slows progression where damage exists |

| Protective Coatings | Application of a protective layer over repaired areas | Shields exposed steel from corrosive elements |

By adhering to a comprehensive maintenance plan and promptly repairing any damage, the risk of reinforcing steel corrosion can be significantly diminished, safeguarding the structural health of concrete edifices for future generations.

Conclusion

Throughout this discussion, it’s evident that the fabric of our urban landscape, concrete, is susceptible to numerous forces that can cause cracks and compromise its structural integrity. The causes are multifaceted, ranging from environmental impacts and material choices to design considerations and beyond. Recognizing these reasons is the cornerstone of maintaining concrete integrity and ensuring the safety and durability of our infrastructure. By delving into the specifics of these causes, we empower ourselves with the knowledge to mitigate risks and preserve the long-term function of our concrete edifices.

Effective managing cracks in concrete is not merely about repair but also about adopting proactive measures that extend from the initial mix design to the final stages of curing and beyond. The durability of concrete structures is a testament to sound engineering practices and attentive maintenance. Adopting such practices not only addresses immediate concerns but also contributes to long-term concrete structure preservation. To ignore these principles is to gamble with the longevity of our built environment—something we can ill afford.

Finally, as stewards of the built environment, it’s our collective responsibility to ensure that the legacy of our construction endures. Embracing a thorough understanding of concrete’s vulnerabilities permits us to craft strategies that shore up its strengths. In doing so, we pave the way for future generations to inherit an infrastructure that stands the test of time, maintaining the integrity and vitality of our cities and communities.

Also, Read,

FAQ

What are some common causes of cracks in concrete columns and beams?

Cracks in concrete columns and beams can arise from a variety of issues, including excessive loads that exceed the design capacity, inadequate reinforcement, shrinkage during the curing process, and environmental influences such as thermal stresses and corrosion of internal steel reinforcing.

Why do concrete slabs develop cracks?

Concrete slabs may crack due to factors like shrinkage during drying, poor concrete mix design, insufficient curing, ground movement or settlement, and overloading. Fluctuations in temperature and moisture can also contribute to the formation of cracks in slabs.

How can environmental conditions affect concrete pavements?

Environmental factors such as temperature variations, freeze-thaw cycles, salt-induced corrosion (in cold climates), and moisture changes can lead to concrete pavement deterioration. These factors contribute to the expansion and contraction of concrete, which can result in cracking over time.

What role does the water-cement ratio play in the durability of concrete?

The water-cement ratio is crucial in determining the strength and durability of concrete. A higher ratio can lead to increased porosity and reduced strength, making the concrete more susceptible to cracking. A lower ratio helps create a denser, more durable concrete mix that is less prone to cracking.

How does inadequate curing contribute to cracks in concrete structures?

Inadequate curing can prevent concrete from reaching its intended strength and durability. Premature drying, inconsistent moisture levels, and improper temperature control during curing can lead to shrinkage cracks and reduce the concrete’s resistance to environmental stresses.

Can structural design flaws cause cracks in concrete beams and columns?

Yes, design flaws such as an inappropriate reinforcement layout, underestimation of loads, or incorrect material specifications can lead to inadequate structural capacity and the development of cracks in concrete beams and columns.

What is the impact of thermal expansion and contraction on concrete structures?

Thermal expansion and contraction occur when concrete experiences temperature fluctuations, causing it to expand when hot and contract when cool. If a structure is not designed to accommodate these movements, it can lead to stress and cracking, particularly resulting in hairline cracks in the concrete.

How does overloading affect concrete floors?

Overloading concrete floors with weights beyond their designed capacity can lead to stress fractures and cracking. It’s essential to understand and adhere to the specified load limits to prevent structural overloading and ensure the longevity of the concrete floors.

Why is ground movement a concern for concrete walls?

Ground movement, including soil settlement and subsidence, can exert uneven pressure on concrete walls, causing them to crack or shift. Addressing these soil-structure interaction concerns during design and construction can help mitigate such problems.

How does the corrosion of reinforcement within concrete structures lead to cracks?

The corrosion of steel reinforcements within concrete can cause the steel to expand, exerting pressure on the surrounding concrete and leading to cracking. Corrosion typically results from moisture and contaminants penetrating the concrete and reaching the steel.