Self-Compacting Concrete

As construction technology continues to evolve, new materials and methods are emerging to make construction work more efficient, cost-effective, and sustainable. One such material is self-compacting concrete (SCC), which has gained popularity in recent years due to its unique properties and benefits.

Self-compacting concrete is a type of concrete that can flow and consolidate under its own weight, without the need for excessive vibration. It is made up of a carefully selected combination of materials such as cement, fine aggregates, water, and chemical admixtures that enhance its flowability and stability.

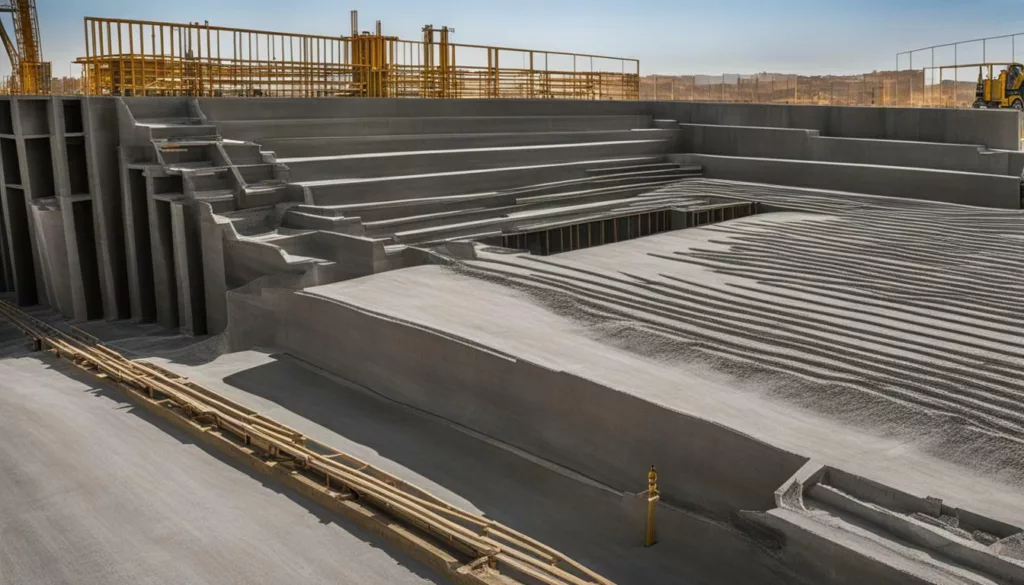

The use of self-compacting concrete has become increasingly prevalent in a variety of construction projects, from high-rise buildings to bridges, tunnels, and precast elements. Its unique characteristics make it a valuable material for complex structures, architectural designs, and precast elements.

In this article, we will explore self-compacting concrete in detail, discussing its materials, properties, applications, as well as its pros and cons. Through this discussion, we hope to provide valuable insights into the use of self-compacting concrete in modern construction projects in India and beyond.

What is Self Compacting Concrete?

In our previous section, we introduced the concept of self-compacting concrete (SCC) and its materials, properties, applications, as well as its pros and cons. Now, let us delve deeper and define what self-compacting concrete is.

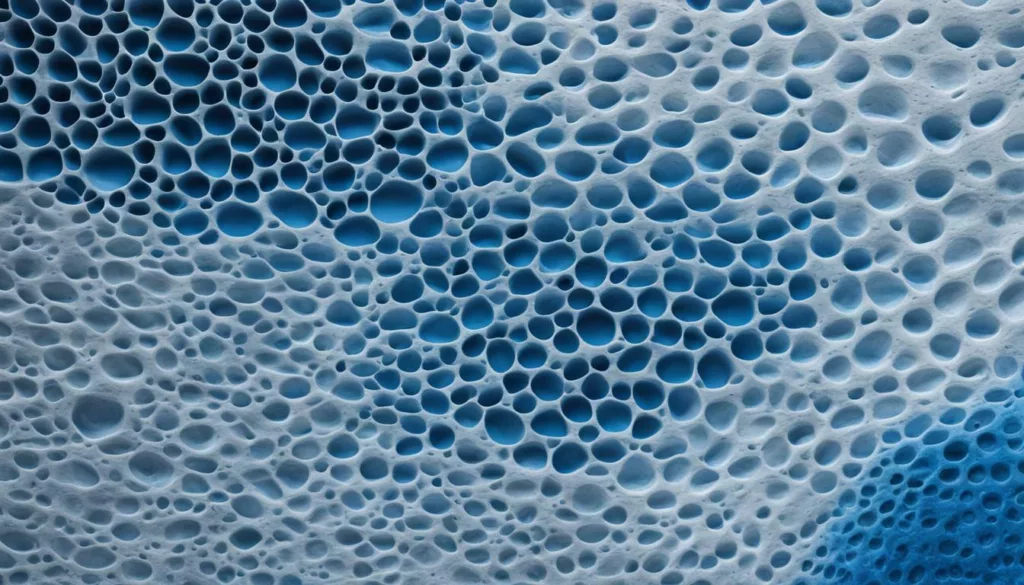

Self-compacting concrete, or SCC, is a highly flowable and self-leveling mixture that is specifically designed to fill and fully consolidate in even the most complex and congested formwork. Unlike traditional concrete, SCC has a unique ability to self-level and maintain its homogeneity without the need for excessive vibration. This results in a highly uniform and defect-free surface finish, which is especially beneficial in architectural applications.

The key to SCC’s exceptional flowability and stability lies in its mix design, which incorporates several key materials and proportions. These include a high volume of fine aggregate, a low water/cement ratio, and specific viscosity-enhancing admixtures.

Overall, self-compacting concrete is a valuable material that offers significant benefits in terms of ease of placement and consolidation, particularly in complex structures and architectural designs. Its unique properties and flowability make it a viable choice for a wide range of construction projects.

Self-compacting concrete (SCC) has revolutionized the way we approach complex construction projects. Its unique properties make it ideal for a wide range of applications, from high-rise buildings to precast elements, and even for repairs and retrofitting. Here are some of the key uses and applications of SCC:

- Complex Structures: SCC is ideal for projects with intricate and complex geometry, where traditional concrete could be difficult to place and consolidate. Its ability to flow and compact itself around even the most complex shapes and corners ensures uniform and high-quality concrete throughout the structure.

- Architectural Designs: SCC can be used to create stunning architectural designs and details, from curved walls and facades to intricate patterns and shapes. Its high flowability and stability enable intricate designs to be achieved with ease while maintaining consistency and structural integrity.

- Precast Elements: SCC is also ideal for precast elements, where consistency and quality are critical factors. It can be used to produce precast walls, beams, columns, and other elements with complex shapes and details, without the need for excessive vibration or compaction.

- Repairs and Retrofitting: SCC can also be used for repairs and retrofitting of existing structures, where access is limited, and traditional concrete placement methods are not feasible. Its flowability and stability enable effective repair of cracks and faults, and it can also be used for grouting and filling voids.

These are just a few examples of the potential uses and applications of self-compacting concrete in modern construction projects. It’s versatility and unique properties have made it an increasingly popular choice among builders, engineers, and architects, and its potential for further innovation and refinement makes it an exciting development in the field of concrete technology.

Self-compacting concrete (SCC) is a highly flowable and stable material that does not require excessive vibration during placement and consolidation. To achieve these unique properties, specific materials and mixed design considerations must be taken into account.

The essential materials required for SCC include fine and coarse aggregates, cement, mineral additives, and chemical admixtures. The proportions of each material should be carefully selected and optimized based on the desired performance and characteristics of the SCC mix.

The mix design process for SCC involves several steps. First, the target performance parameters, such as slump flow and strength, must be determined. Next, the appropriate aggregate proportions and gradations are selected, followed by the determination of the optimal cement content and type. Mineral additives are then added to enhance specific properties such as workability and durability. Finally, chemical admixtures such as superplasticizers and viscosity modifiers are added to achieve the desired flowability and stability.

The proportioning of materials and the overall mix design for SCC should be carefully tested and optimized using trial mixes. The process takes into account factors such as the aggregate shape, size, and grading, as well as the rheological properties of the mixture.

It is worth noting that the mix design process for SCC is more complex and involved than that of traditional concrete. The use of advanced testing methods, such as rheometers and slump flow tests, is necessary to ensure that the SCC mix meets the required performance standards.

Overall, the careful selection of materials and mix design optimization is crucial for achieving the desired properties and performance of self-compacting concrete.

In this section, we will delve into the key properties of self-compacting concrete (SCC). SCC exhibits distinct characteristics that differentiate it from traditional concrete.

Workability: SCC offers excellent workability, allowing it to flow and fill formwork without the need for excessive vibration. This property makes it ideal for complex structures and architectural designs.

Segregation resistance: SCC has high resistance to segregation, ensuring that the mix remains uniform and consistent throughout the placement process.

Strength development: SCC exhibits comparable or even superior strength development compared to traditional concrete. The optimized mix design and absence of compaction also contribute to its strength.

Durability: SCC has excellent durability, with reduced permeability and a lower risk of cracking. This property makes it suitable for long-lasting structures, such as bridges and tunnels.

Sustainability: SCC has the potential to be more sustainable than traditional concrete, with lower water-cement ratios and reduced need for formwork. Additionally, the use of supplementary cementitious materials can further enhance its sustainability.

To better understand the properties of SCC, various tests can be conducted, including slump flow tests, V-funnel tests, and compressive strength tests. These tests help to ensure that the SCC mix meets the desired specifications and performance criteria.

“SCC exhibits excellent workability, segregation resistance, strength development, durability, and sustainability.”

Advantages of Self-Compacting Concrete

At its core, self-compacting concrete (SCC) offers numerous benefits over traditional concrete. These advantages can be attributed to its unique flowable and self-leveling properties, which allow it to consolidate without the need for excessive vibration. Here are some of the main advantages of using SCC in construction projects:

- Reduced Labor and Equipment Requirements: SCC can significantly reduce the need for manpower and equipment during placement and consolidation, which can save time and money. Its flowable nature allows it to easily fill and consolidate even the most intricate and congested forms, resulting in a more efficient construction process overall.

- Improved Quality: The self-consolidating nature of SCC minimizes the risk of honeycombing, voids, and other defects that can result from traditional consolidation methods. This leads to a more uniform and durable finished product with improved strength and durability.

- Enhanced Construction Speed: Due to its ease of placement and consolidation, SCC can speed up construction times by reducing the amount of time required for formwork assembly and removal, as well as for vibration and finishing operations.

- Greater Design Flexibility: SCC’s flowability allows it to more easily fill complex forms and intricate shapes, making it ideal for architectural and decorative concrete applications. Its superior aesthetic qualities also make it an attractive choice for exposed concrete surfaces.

- Improved Safety: By reducing the need for manual consolidation and vibration, SCC can help improve job site safety by minimizing the risk of worker injury or fatigue.

- Environmental Sustainability: SCC can be formulated to reduce the carbon footprint of a construction project by incorporating recycled materials, industrial byproducts, and other environmentally friendly additives. Its durability and longevity also contribute to the sustainability of a structure over its lifespan.

Overall, the many advantages of self-compacting concrete make it a valuable material for a wide range of construction projects. Its ability to flow and consolidate without the need for excessive vibration has the potential to revolutionize modern construction methods and offer improved aesthetics, durability, and efficiency.

Despite its many advantages, self-compacting concrete is not without its drawbacks. Here are some of the disadvantages of using SCC:

| Disadvantages | Description |

|---|---|

| Higher Material Costs | The materials used to make self-compacting concrete are often more expensive than those used for traditional concrete. This can increase the overall cost of the project. |

| Potential for Segregation | If the mix design of SCC is not properly optimized, there is a risk of material segregation during the pouring process. This can lead to inconsistencies in the final product and affect its durability. |

| Limitations in Certain Applications | Self-compacting concrete is not suitable for all applications. For example, it may not be the best choice for structural elements that require high compressive strength or for projects that involve heavy reinforcement. |

It’s important to carefully consider these potential disadvantages when deciding whether to use self-compacting concrete for a construction project. However, with proper mix design and testing, SCC can offer numerous benefits that outweigh these drawbacks.

Testing is an essential step in ensuring the quality and performance of self-compacting concrete (SCC). Here, we will explore some of the commonly used testing methods for SCC.

One of the essential tests for SCC is the slump flow test, which measures the horizontal flow of the concrete mixture. This test assesses the ability of the concrete to spread and fill the formwork without the need for external vibration. The result of the test helps to determine the workability of the concrete.

The V-funnel test is another method of assessing the flowability of SCC. This test measures the time taken for the concrete to flow through a V-shaped funnel. The flow time is an indication of the viscosity of SCC, which is influenced by its specific mix design.

Other tests commonly used for SCC include the L-box test, J-ring test, and U-box test. These tests assess the resistance to segregation and the ability of the concrete to maintain its stability and homogeneity. By conducting these tests, engineers and contractors can ensure that the SCC meets the required standards and specifications.

Self-Compacting Concrete Mix Design Procedure

Designing a self-compacting concrete mix requires careful consideration of various factors, including the desired fresh and hardened properties, the specific application, and the availability of materials. The following steps outline the general process for designing an SCC mix:

- Determine the characteristics of the materials: The properties of the cement, aggregates, and admixtures used in the mix should be analyzed to ensure they meet the required standards for SCC. The gradation, shape, texture, and specific gravity of the aggregates are especially critical for achieving the desired flowability and stability.

- Estimate the proportions: The initial proportions of the mix components can be estimated based on previous experience, published guidelines, or trial batches. The aggregate-cement ratio, water-cement ratio, and superplasticizer dosage are the most important variables to consider.

- Conduct trial batches: Several trial batches should be prepared and tested to determine the optimal proportions for the SCC mix. The slump flow test, the T50cm slump flow time, the V-funnel test, and the L-box test are commonly used to assess the flowability, passing ability, and filling ability of the mix. The hardened properties, such as compressive strength, elastic modulus, and durability, should also be evaluated.

- Adjust the mix proportions: Based on the results of the trial batches, the mix proportions can be adjusted to achieve the desired mix design. The final mix should have the required flowability, stability, workability, and strength properties specified in the project requirements.

It is worth noting that the mix design procedure for SCC is still evolving, and research is ongoing to optimize the mix proportions and improve the predictability of the fresh and hardened properties. Advanced techniques such as rheology modeling, artificial neural networks, and genetic algorithms are being explored to enhance the efficiency and accuracy of SCC mix design.

In recent years, self-compacting concrete (SCC) has gained popularity in the Indian construction industry due to its numerous advantages over traditional concrete. Its unique properties make it suitable for various applications, including complex structures, precast elements, and architectural designs.

One notable example of SCC’s successful application in India is the construction of the Bandra-Worli Sea Link, a cable-stayed bridge in Mumbai. The project utilized 90,000 cubic meters of SCC, which allowed for efficient construction without compromising the quality of the structure.

Another significant project that made use of SCC is the Chennai Metro Rail, which involved the construction of elevated viaducts and underground stations. SCC was specially designed and optimized for the project’s requirements, resulting in faster construction and improved durability.

Furthermore, SCC has the potential to address some of the challenges faced by the Indian construction industry, such as the shortage of skilled labor and the need for faster construction. By reducing the need for manual labor and equipment, SCC can improve construction productivity and quality.

However, the adoption of SCC in India is still relatively low compared to other countries. Some of the reasons for this include the higher material costs and the lack of awareness and expertise in SCC’s mix design and testing methods.

Despite these challenges, the potential for SCC’s application in India is vast, and ongoing research and development efforts aim to address these issues. With its ability to enhance construction quality, efficiency, and durability, the use of SCC has the potential to revolutionize the Indian construction industry.

In conclusion,

we can safely say that self-compacting concrete (SCC) is a valuable material for the construction industry. Its unique properties and ease of placement make it ideal for complex structures, architectural designs, and precast elements. However, it is essential to pay careful attention to the mix of design and testing methods to ensure optimal performance and quality.

The cost implications of using SCC should also be considered, as it may be more expensive than traditional concrete. Despite these challenges, the use of SCC has the potential to revolutionize the construction industry in India and beyond. Its ability to reduce labor and equipment requirements, enhance quality, and improve construction speed make it a promising material for the future.

Overall, we believe that SCC should be seriously considered in any modern construction project. Its numerous advantages and potential future impact make it a material worth exploring further.

Thanks For the Great Attention!

Also, Read

1000Sqft house construction cost in 2022