If you’re involved in the construction industry, you’ve likely heard of shotcrete. It’s a versatile construction material that offers several advantages over traditional concrete applications. Sprayed concrete is a highly durable and cost-effective solution that can be used for a variety of applications, from tunnels and mines to swimming pools and decorative enhancements.

Shotcrete is a type of concrete that is sprayed onto a surface at high velocity using compressed air. There are two main types of shotcrete: dry-mix and wet-mix. Each has its unique advantages and disadvantages. This guide will delve into the properties, applications, advantages, and disadvantages of Sprayed concrete, as well as its environmental impact and future trends in Sprayed concrete technology.

Key Takeaways:

- Sprayed concrete is a versatile construction material that offers several advantages over traditional concrete applications.

- There are two main types of shotcrete: dry-mix and wet-mix, each with its unique advantages and disadvantages.

- Sprayed concrete is highly durable and cost-effective, making it an ideal solution for a wide range of applications, from tunnels and mines to swimming pools and decorative enhancements.

- Construction professionals can make informed decisions regarding the use of shotcrete in their projects by considering its properties, applications, advantages, and disadvantages.

- It is essential to maintain and repair Sprayed concrete structures to ensure their longevity and structural integrity.

Understanding Shotcrete

If you’re not familiar with construction and concrete application methods, you may be wondering what exactly shotcrete is. Sprayed concrete, also called gunite, is a construction material that is pneumatically applied through a hose onto a surface at a high velocity. It’s essentially a concrete mixture that is sprayed onto a surface instead of being poured, making it an efficient and versatile building method.

Compared to traditional methods of concrete application, shotcrete offers several advantages, including reduced construction time, improved strength and durability, and increased flexibility in design. Overall, it’s a reliable solution that’s used in a variety of construction projects, from building structures to swimming pools.

“Sprayed concrete is both an art and a science,” says James Wight, a professor of civil engineering at the University of Michigan. “People who are good at it are a combination of craftsmen and engineers.”

Types of Shotcrete: Dry-Mix Process

The dry-mix process, also known as the gunite technique, involves mixing dry ingredients before adding water through a nozzle. The mixing happens in a specially designed gunite machine, which propels the mixture using compressed air to the application site. Dry-mix Sprayed concrete is commonly used in areas with restricted access, such as slopes and tunnels, where traditional concrete pouring methods are difficult to achieve.

This type of shotcrete offers several advantages, including superior bonding strength and excellent application efficiency. It also allows for precise placement, producing a dense and highly durable structure. However, the dry-mix process can result in a significant amount of rebound, which is material that fails to adhere to the surface during application. This can result in unwanted waste and additional cleanup requirements.

The advantages and limitations of the dry-mix process can be summarized in the following table:

Advantages of Dry-Mix Shotcrete:

- Excellent bonding strength

- Precise placement control

- High application efficiency

- Produces dense and durable structures

Disadvantages of Dry-Mix Shotcrete:

- Higher rebound rates compared to wet-mix Sprayed concrete

- Requires skilled applicators

- Initial setup costs for equipment and materials

- Not suitable for large-volume applications

“Dry-mix shotcrete is an ideal solution for enhancing the strength and durability of structures in areas with restricted access. However, it requires proper application techniques and equipment to avoid material waste and ensure optimal performance.”

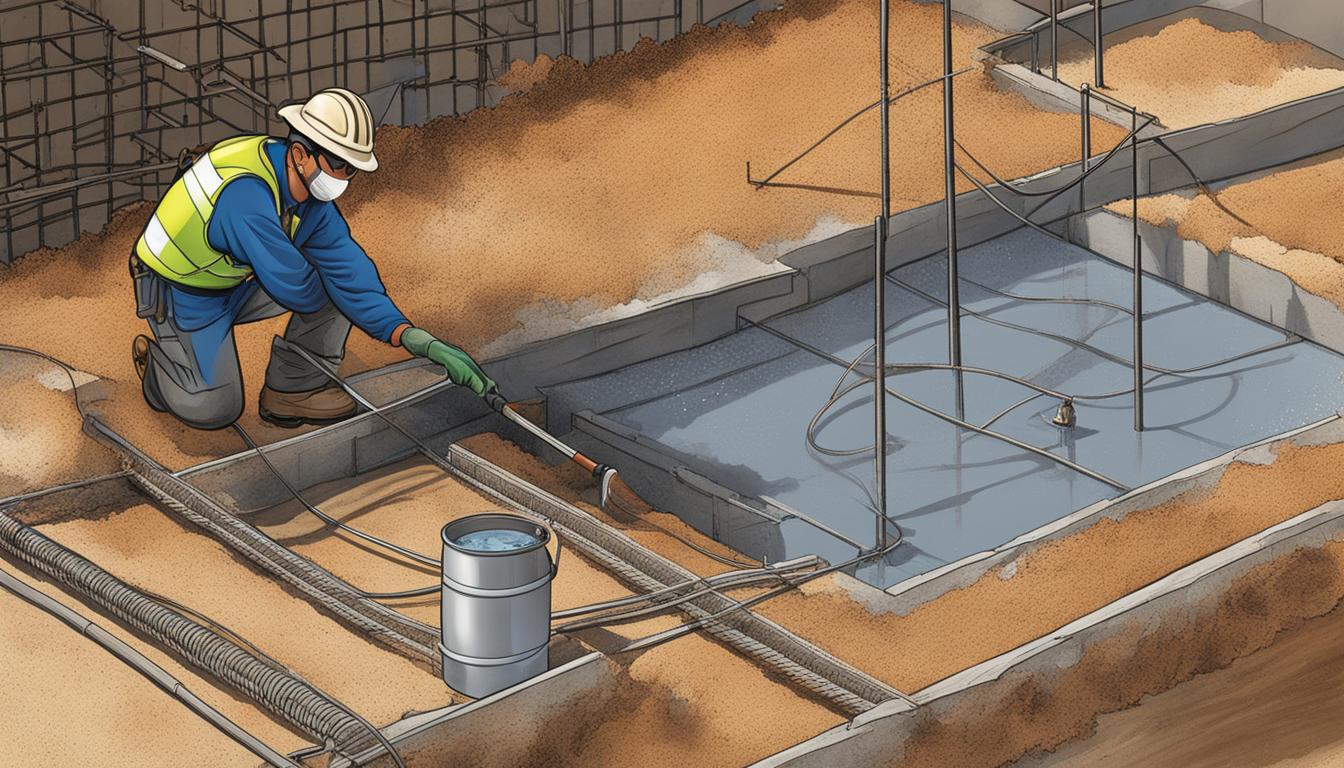

Types of Shotcrete: Wet-Mix Process

In the wet-mix process, all the shotcrete components, including the cement, water, and aggregates, are mixed and transported to the nozzle via a concrete pump. The nozzle operator then adds the compressed air to create a spray pattern, resulting in a wet layer of material that is applied to the surface.

This technique offers several unique advantages over the dry-mix process. For example, the wet-mix process provides better bonding to the substrate, enabling it to adhere well to reinforced steel surfaces. Additionally, this method produces a more uniform and consistent texture, ensuring high-quality finishes. Wet-mix shotcrete is also less prone to rebound, making it more efficient and cost-effective.

However, one disadvantage of this process is its slow setting time, which may result in extended wait times before starting the next stage of the project. Additionally, the wet-mix process can result in a higher level of dust production during the mixing and spraying stages.

In terms of applications, the wet-mix process is often used for structural support, swimming pools, and other concrete structures where a smooth and consistent finish is required. Moreover, it is ideal for tunneling, particularly in rugged terrain where the risk of sloughing is high. The wet-mix process can also be used for the construction of vertical surfaces, including walls, beams, girders, and columns.

Properties of Sprayed concrete

Shotcrete is a versatile construction material with unique properties that make it an excellent choice for various applications. Understanding the properties of sprayed concrete is crucial to determine its suitability for specific construction projects. In this section, we will explore the main properties of shotcrete and their significance.

Strength

The compressive strength of sprayed concrete can vary depending on the mix design, curing conditions, and application method. Generally, shotcrete has excellent compressive strength, often exceeding that of traditional concrete. Its high strength also provides resistance against erosion and abrasion.

Durability

Shotcrete is highly durable and can withstand harsh conditions such as freeze-thaw cycles, seismic activity, and extreme temperatures. Its durability is attributed to the low water-cementitious ratio, which creates a dense and impermeable material with reduced shrinkage potential.

Water Permeability

sprayed concrete has a low water-cementitious ratio, making it highly resistant to water penetration. This property makes it an ideal material for water containment and control structures such as swimming pools, dams, and tunnels.

Adhesion

Shotcrete exhibits excellent bonding properties, allowing it to adhere to various surfaces without the need for extensive surface preparation. Its high bonding strength also makes it a suitable material for reinforced concrete structures and repair applications.

Potential for Shrinkage

Sprayed concrete has a low shrinkage potential due to its low water-cementitious ratio. However, the potential for shrinkage increases with prolonged curing periods, which can lead to cracks. Proper curing practices and mixed designs can minimize this occurrence.

| Properties | Advantages |

|---|---|

| High Strength | Reduced maintenance costs |

| Durability | Long-lasting structures |

| Water Permeability Resistance | Water containment and control structures |

| Adhesion | Reduced need for surface preparation |

| Low Potential for Shrinkage | Minimizes cracking |

By understanding the properties of shotcrete and its significance, construction professionals can make informed decisions regarding its use in various applications.

Applications of sprayed concrete

Shotcrete is a versatile construction material that offers an extensive range of applications. Some of the primary applications where sprayed concrete excels include:

| Application | Description |

|---|---|

| Tunneling | sprayed concrete is frequently used as a primary support structure during tunnel excavation, providing a protective lining for the excavated space. It also offers an effective solution for stabilizing the ground surrounding the tunnel. |

| Slope Stabilization | Shotcrete is an effective solution for preventing soil erosion, rockfall, and other hazards on slopes. Its adaptability means it can be applied to both gentle and steep slopes, offering long-term stabilization. |

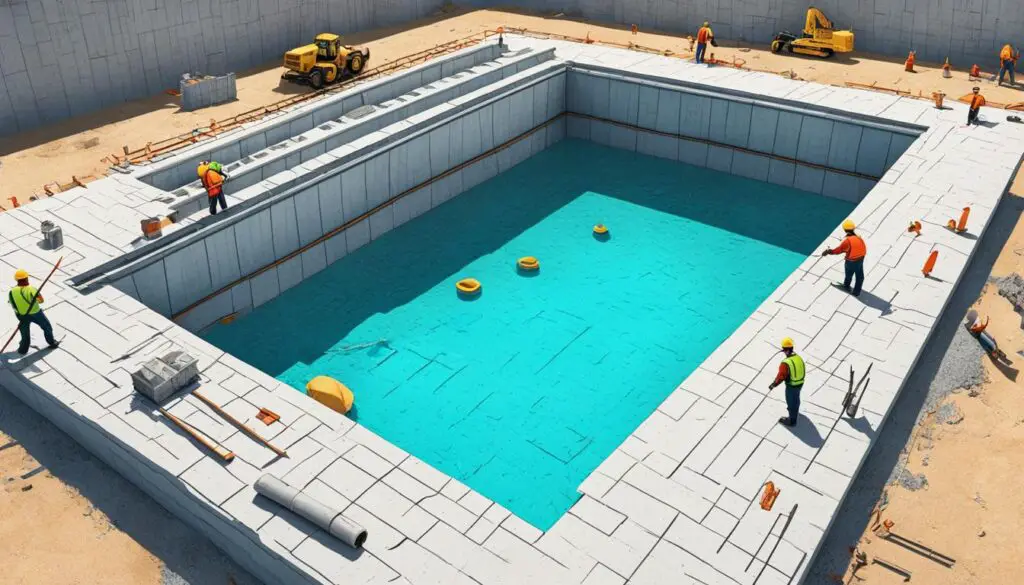

| Swimming Pool Construction | sprayed concrete is a popular material for constructing swimming pools due to its durability, versatility, and speed of application. Its adaptability means it can be used in a wide range of aquatic settings, including residential and commercial swimming pools. |

| Architectural Enhancements | Shotcrete is an effective material for embellishing architectural features, such as walls, ceilings, and sculptures, due to its ability to create intricate shapes and designs. It can be used to mimic natural stone, concrete, or any other material to complement the design and aesthetic appeal of the structure. |

| General Construction | sprayed concrete can be used for various purposes in general construction, such as maintaining the structural integrity of buildings, bridges, and other infrastructure. It is an effective solution for repairing and strengthening existing structures or providing a protective coating against environmental factors. |

In short, the adaptability and durability of shotcrete allow it to be used in a diverse array of construction works, making it a valuable material in any construction project.

Advantages of Shotcrete

sprayed concrete offers numerous advantages over traditional concrete application methods. Some of the key benefits of using shotcrete in construction include:

- Reduced Construction Time: Sprayed concrete is easier and quicker to apply than conventional concrete, allowing for faster project completion times.

- Versatility: Shotcrete can be used in a variety of applications, including forming irregular shapes and surfaces that may not be possible with traditional concrete.

- Improved Structural Integrity: Sprayed concrete provides a high level of durability and strength, increasing the longevity and safety of structures.

- Cost-Effectiveness: The increased efficiency of shotcrete application can lead to lower labor and material costs, making it a cost-effective option for certain projects.

In addition, sprayed concrete also offers improved workability and reduced material waste, helping to optimize project outcomes. Overall, shotcrete is an innovative and reliable construction solution that continues to gain popularity in the industry.

Disadvantages of Shotcrete

While sprayed concrete offers numerous benefits in construction, it’s important to consider its potential drawbacks. Here are some of the disadvantages of using shotcrete:

- The need for skilled applicators: sprayed concrete application requires skilled technicians who are trained to operate the equipment and apply the material. Without experienced applicators, the quality of the finished product may suffer.

- Initial setup costs: The initial investment required for shotcrete equipment and the installation of support structures can be higher than that of traditional concrete application methods.

- Potential for rebound: Sprayed concrete can rebound or bounce off the surface it’s being applied to, creating a safety hazard and reducing the efficiency of the application process.

By understanding both the advantages and disadvantages of shotcrete, you can make informed decisions about its use in your construction projects.

Shotcrete in Modern Construction

Sprayed concrete has revolutionized the construction industry, providing versatile, durable, and cost-effective solutions to a range of structural challenges. Numerous applications of shotcrete have been utilized in modern construction, showcasing its practical and innovative capacity.

Shotcrete in Tunnel Stabilization

The application of sprayed concrete has been widely used in tunneling projects, providing fast and efficient support to tunnel linings. Shotcrete has proven to be very reliable in stabilizing these critical infrastructures, reducing construction time, and improving safety for workers and users alike.

| Location | Application |

|---|---|

| Chuo Shinkansen Tunnel, Japan | Stabilization of high-speed rail lines |

| Leitha Power Tunnel, Austria | Support of tunnel excavation area |

Shotcrete in Swimming Pool Construction

The use of shotcrete in swimming pool construction has been a game-changer, offering flexibility in design, shape, and depth. Sprayed concrete has been instrumental in creating decorative swimming pools with variable surfaces and textures, that can be finished with tiles, stones, or other finishing materials.

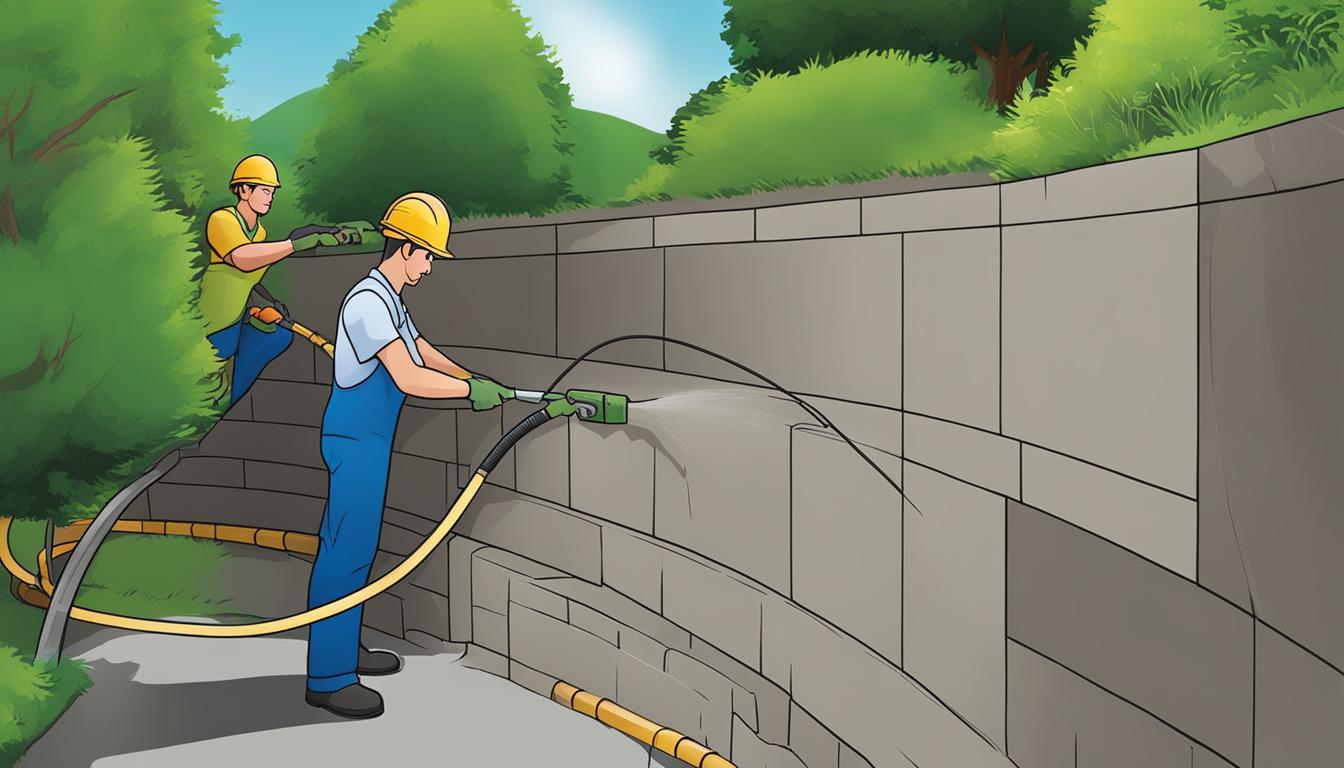

Shotcrete in Slope Protection

The use of sprayed concrete has been also widely used in slope protection, offering to stabilize the soil and prevent landslides in areas where the risk for such events is high. Shotcrete can be applied on exposed slopes to create a more stable and contoured surface that blends into the natural environment.

Shotcrete in Architectural Enhancements

The application of sprayed concrete has been increasingly used to create architectural enhancements that require the creation of complex shapes and structures. Shotcrete allows the realization of intricate designs that would otherwise be impossible with conventional methods, offering cost-effectiveness and versatility.

The examples provided above illustrate just a few of the myriad applications of sprayed concrete in modern construction. As developers continue researching its adaptability and flexibility, the potential for creative and innovative ways to apply shotcrete will only continue to grow.

Environmental Impact of Shotcrete

As with any type of construction material, the environmental impact of sprayed concrete must be carefully considered. While the use of shotcrete can result in reduced material and labor costs, there are potential downsides that can have negative environmental consequences.

Firstly, the carbon footprint of shotcrete can be significant, as large amounts of energy are required to manufacture and transport the necessary materials, particularly cement. Additionally, the production of cement involves the release of carbon dioxide, a greenhouse gas that contributes to climate change.

Furthermore, the application process of sprayed concrete can lead to the generation of waste materials, including rebound and overspray. While measures can be taken to limit the amount of waste generated, it is still a potential issue that must be addressed.

On the positive side, sprayed concrete can have a lower environmental impact compared to traditional concrete due to its ability to reduce material usage, particularly rebar. Additionally, the durability and strength of shotcrete structures means they have a longer lifespan, reducing the need for frequent repairs and replacements.

To minimize the environmental impact of sprayed concrete, it is vital to carefully plan and manage the construction process, including the sourcing of materials, transportation methods, and waste disposal. By taking a proactive approach, it is possible to significantly reduce the environmental impact of shotcrete without sacrificing its many benefits.

Innovations and Future Trends in Shotcrete

Shotcrete has come a long way since its inception in the early 1900s. As technology continues to evolve, so do the innovations in sprayed concrete applications. In recent years, a focus on improving mix designs, utilizing additives, and increasing automation has resulted in remarkable advancements in shotcrete technology.

One area of significant progress is the development of high-performance sprayed concrete. New admixtures and fibers have greatly improved the strength, durability, and ductility of shotcrete structures. High-performance shotcrete is increasingly used in large-scale construction projects where strong, durable, and high-strength materials are required. This type of shotcrete is also ideal for seismic retrofitting.

The use of automation in sprayed concrete applications has also become more prevalent. Robotic sprayed concrete application eliminates the need for manual labor and increases efficiency, accuracy, and safety on the job site. Automation has also resulted in reduced material waste and better quality control.

Did you know? One of the most significant innovations in shotcrete is the development of synthetic fibers. These fibers add tensile strength to concrete, which significantly enhances its toughness and ductility, making it an ideal material for construction in high-risk seismic zones.

| Future Trends in Shotcrete | Description |

|---|---|

| Nanotechnology | The use of nanotechnology in sprayed concrete could help improve its properties and reduce its carbon footprint. Nanoparticles can be added to the mix to enhance shotcrete’s strength, durability, and permeability while reducing the amount of cement required. |

| 3D Printing | The use of 3D printing technology in sprayed concrete applications could change the way we construct buildings and infrastructure. This technology could allow for complex and intricate designs to be created with greater speed and accuracy than traditional methods. |

| Self-Healing Concrete | Researchers are exploring the use of bacteria that can produce calcium carbonate to create self-healing concrete. This innovative technology could reduce the need for frequent maintenance and repair of shotcrete structures and increase their lifespan. |

As we move forward, it is clear that shotcrete will continue to play an important role in modern construction. With ongoing innovations and advancements, we can anticipate even more groundbreaking achievements in the field of sprayed concrete.

Case Studies: Successful sprayed concrete Projects

If you are interested in the practical application of shotcrete, reviewing case studies of successfully sprayed concrete projects can shed light on its numerous benefits and diverse applications. Our selection of case studies highlights unique challenges, solutions, and the benefits realized through the use of sprayed concrete.

Project 1: Plymouth Creek Restoration, Minnesota

This project consisted of restoring a section of Plymouth Creek, MN, that had been damaged by erosion. sprayed concrete was used extensively to shape the creek bed and protect the surrounding banks. The dry-mix process was used, providing high-quality and consistent shotcrete. The project was completed on time, and the shotcrete’s efficiency reduced the need for additional reinforcements, resulting in considerable cost savings.

Project 2: Olympic Village, Vancouver

sprayed concrete was critical in the construction of the award-winning Olympic Village in Vancouver, a sustainable urban development project that served as the athletes’ residential quarters during the 2010 Vancouver Winter Olympics. The wet-mix shotcrete process was used to construct a network of tunnels, providing transportation to and from the upcoming venue. sprayed concrete was also used in building the recreation center, which had unique architectural design features. The project demonstrated shotcrete’s versatility, efficiency, and low environmental impact.

Project 3: Ritz-Carlton, Riyadh

Shotcrete played a critical role in constructing the Ritz-Carlton Riyadh, a 65,000 square-meter hotel in Saudi Arabia, as it met a unique challenge of the project. The hi-tech sprayed concrete process, with multiple admixtures, was used for the building’s anti-terrorist barriers. The barriers provided blast resistance, saving lives from a potential terrorist attack. The project was completed on time, and the shotcrete’s efficiency provided additional reinforcement to the building structure.

These case studies demonstrate shotcrete’s diverse applications across different projects, from erosion control to urban development and anti-terrorist defense measures. sprayed concrete proved to be highly effective, reliable, and cost-efficient in challenging situations.

Training and Certification for Shotcrete Application

As with any specialized technique in construction, shotcrete application requires proper training and certification to ensure that it is done safely, efficiently, and correctly. The sprayed concrete application involves a unique set of skills, including knowledge of mix design, equipment operation, and application technique.

A variety of organizations and training providers offer shotcrete training and certification programs that cover safety protocols, application techniques, and equipment handling. These providers offer certifications ranging from entry-level to advanced, ensuring proficiency at every level of Sprayed concrete application.

Individuals applying shotcrete must be trained in proper equipment operation, including the handling of the construction equipment and application tools. Training courses focus on hands-on experience, allowing individuals to gain practical knowledge and skillsets that pertain to the application of Sprayed concrete.

Having properly trained and certified individuals perform shotcrete applications ensures that the application is safe and effective. This reduces the risk of accidents, injuries, and liabilities that are associated with improper application. Additionally, it leads to better quality work and ensures that the project is completed correctly and on time.

By obtaining training and certification in Sprayed concrete application, construction professionals can create a safer work environment, build more efficient and effective structures, and gain greater credibility with clients and peers.

Example of Shotcrete Training and Certification Providers

| Training Provider Name | Location | Certification Details |

|---|---|---|

| American Shotcrete Association | USA | The American Shotcrete Association (ASA) offers a range of certification programs that certify proficiency in Sprayed concrete application at various levels. |

| The Concrete Centre | UK | The Concrete Centre provides training courses and certification in Sprayed concrete applications that cover fundamental techniques, mix designs, and safety protocols. |

| The Shotcrete Institute | USA | The Shotcrete Institute offers a range of certification programs that are designed to ensure proficiency in Sprayed concrete application for both novice and experienced practitioners. |

Maintenance and Repair of Shotcrete Structures

As with any construction material, shotcrete structures require regular maintenance to ensure their longevity and safety. Common issues with Sprayed concrete structures include cracking, spalling, and erosion. These issues can occur due to a variety of factors, including weather exposure, moisture ingress, and improper application.

It is important to perform regular inspections of shotcrete structures to identify and address these issues before they worsen. Inspections should be conducted by a qualified professional who can assess the structural integrity of the shotcrete and identify any potential areas of concern.

If repairs are necessary, they must be performed by professionals experienced in Sprayed concrete repair methods. The repair process will vary depending on the extent and nature of the damage but can include cleaning and preparation of the affected area, adding a bonding agent, and applying new shotcrete to the damaged area.

It is also important to consider preventative maintenance measures for shotcrete structures, such as applying sealants or coatings to mitigate the effects of weather exposure or moisture ingress.

| Common Issues | Recommended Repair Methods |

|---|---|

| Cracking | Routing and sealing, adding additional reinforcing elements |

| Spalling | Removal of damaged material, surface preparation, applying new Sprayed concrete |

| Erosion | Application of protective coatings or sealants, identification and mitigation of root causes |

Regular maintenance and repair of Sprayed concrete structures is critical to ensure their safety and longevity. Inspections should be conducted by qualified professionals, and repairs should only be performed by experienced shotcrete contractors.

Conclusion

Congratulations, you have now gained a comprehensive understanding of Sprayed concrete, including its various types, properties, applications, advantages, and disadvantages. By carefully considering the information presented in this guide, you can make informed decisions regarding the use of Sprayed concrete in your construction projects.

Remember, shotcrete is a versatile and cost-effective option with tremendous potential for enhancing the structural integrity of your projects. When using Sprayed concrete, it is imperative to consider the specific conditions of your project and select the appropriate type of shotcrete to achieve the desired results.

Don’t forget about the importance of proper training and certification for Sprayed concrete application to ensure safe and efficient practices. Additionally, proactive maintenance and timely repairs can help extend the lifespan of your shotcrete structures and optimize their performance.

As technology and innovation continue to revolutionize the construction industry, we can expect to see even more advancements and applications of Sprayed concrete in the future. So, keep an eye out for new developments and possibilities that could further improve the performance and sustainability of your construction projects.

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning

Also, Read,

FAQ

What is shotcrete?

Sprayed concrete is a construction material that is applied through a high-velocity pneumatic process. It is a mixture of cement, aggregates, and water, sprayed onto a surface using a wet-mix or dry-mix process.

What are the types of shotcrete?

There are two main types of Sprayed concrete: the dry-mix process and the wet-mix process.

What is the dry-mix process of shotcrete?

In the dry-mix process, the dry ingredients (cement and aggregate) are mixed separately from the water. This mixture is then fed into a nozzle, where compressed air is used to propel it onto the surface. Water is added to the nozzle, ensuring proper hydration.

What is the wet-mix process of Sprayed concrete?

In the wet-mix process, all ingredients (cement, aggregate, and water) are thoroughly mixed before being fed into the nozzle. Compressed air is used to propel the mixture onto the surface, resulting in a highly adhesive and dense material.

What are the advantages of Sprayed concrete?

Shotcrete offers numerous advantages, including enhanced structural integrity, reduced construction time, improved bond with existing surfaces, versatility in application, and cost-effectiveness.

What are the disadvantages of shotcrete?

Despite its many benefits, Sprayed concrete also has some disadvantages, such as the need for skilled applicators, initial setup costs, potential rebound (overspray), and limitations in certain applications.

What are the properties of Sprayed concrete?

Sprayed concrete exhibits excellent compressive strength, durability, adhesion, and resistance to water penetration. However, it may also experience shrinkage and cracking under certain conditions.

What are the applications of Sprayed concrete?

Sprayed concrete is commonly used in various applications, including tunneling, slope stabilization, swimming pool construction, architectural enhancements, repair and restoration of structures, and more.