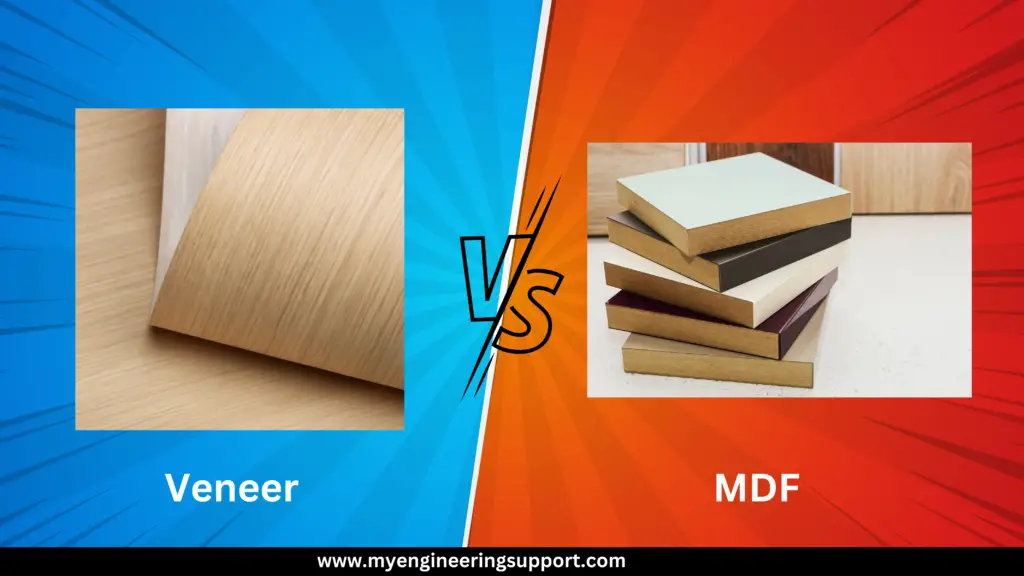

Veneer V/s MDF (Medium Density Fiberboard)

Introduction

Veneer v/s MDF (Medium Density Fiberboard) are two different materials commonly used in furniture and cabinetry.

Veneer is a thin layer of real wood that is bonded to a substrate, such as plywood or MDF, to create a natural wood finish. It offers a high-quality, authentic appearance, showcasing the beauty of the wood grain. A veneer is durable, can be stained or finished, and is available in various wood species. However, it is generally more expensive than other options and may be susceptible to damage from moisture.

MDF, on the other hand, is an engineered wood product made from wood fibers mixed with a resin binder and compressed under high pressure. It is affordable, has a smooth and uniform surface, and is easy to work with. MDF is versatile and can be painted, laminated, or veneered to achieve different looks. It is also more stable and less prone to warping or splitting compared to solid wood. However, MDF is not as strong as solid wood and may not hold screws or nails as well.

The choice between veneer and MDF depends on your specific requirements. If you prioritize a natural wood appearance and are willing to invest in a higher-quality material, veneer is a good choice. If cost, versatility, and ease of customization are more important to you, MDF can be a suitable option.

1). Composition

1.1). Composition of Veneer

Veneer is a thin layer of real wood that is typically obtained by slicing or peeling logs. It is made by bonding these thin slices of wood, called veneer sheets, onto a substrate such as plywood or MDF. Veneer sheets can be sourced from various tree species, providing a wide range of textures, colors, and grain patterns. Some common types of veneer include oak, maple, cherry, and walnut.

The composition of the veneer primarily consists of the natural wood fibers and cell structures found in the particular tree species it is derived from. The veneer sheets are carefully cut to ensure a consistent thickness and are then adhered to the substrate using adhesives, such as wood glue or resin. This bonding process creates a strong and durable surface that retains the natural characteristics and beauty of the wood.

1.2 Composition of MDF

MDF is a man-made composite material that is composed of wood fibers, resin binders, and other additives. It is manufactured by breaking down wood into fibers and combining them with a synthetic resin adhesive under high pressure and temperature. The resulting mixture is then formed into boards or panels of various thicknesses.

The primary component of MDF is wood fiber, which is obtained from hardwood or softwood sources. These wood fibers are finely ground and then combined with a resin binder, typically urea-formaldehyde or phenol-formaldehyde. The resin helps to bind the fibers together and provides strength and stability to the MDF. Additionally, additives such as wax, pigments, and fillers may be included in the mixture to enhance certain properties or improve processing.

MDF is known for its uniform density and smooth surface, making it an ideal material for painting, veneering, or laminating. It has consistent strength and dimensional stability, which makes it less prone to warping or splitting compared to solid wood. However, MDF is susceptible to moisture and should be protected with a suitable finish or coating to prevent swelling or deterioration.

In summary, a veneer is a thin layer of real wood bonded to a substrate, while MDF is a man-made composite material composed of wood fibers and resin binders. Veneer retains the natural beauty and characteristics of the wood it is derived from, while MDF offers uniform density and smooth surfaces. The choice between veneer and MDF depends on factors such as desired aesthetics, budget, and the intended application of the material.

2). Fabrication

Veneer is a thin layer of real wood that is sliced or peeled from a log. The process begins with selecting high-quality logs and cutting them into thin sheets using a slicing or peeling machine. Slicing produces veneer with a straight grain pattern while peeling results in a more irregular grain pattern.

The veneer sheets are then dried, glued onto a substrate (such as plywood or MDF), and pressed to create a strong bond. Veneer offers a natural and high-end appearance, showcasing the beauty of real wood. It can be stained, varnished, or finished to enhance its aesthetic appeal. Additionally, veneer allows for some repair and refinishing options, although it is generally more delicate than solid wood.

When it comes to fabrication, veneer requires skilled craftsmanship to cut and apply the sheets accurately. The process involves attention to detail, precision, and careful handling to achieve seamless and aesthetically pleasing results. It is a labor-intensive process that adds to the cost of the final product.

MDF, on the other hand, is an engineered wood product made from wood fibers combined with resins and binders. The fabrication process involves grinding wood fibers into a fine consistency, mixing them with resins, and forming the resulting mixture into panels under high pressure and temperature. MDF panels have a dense and uniform composition, providing excellent stability and smoothness. They are available in various thicknesses and can be easily shaped and machined, allowing for intricate designs.

MDF fabrication involves precision cutting and shaping using woodworking tools and machinery. It is a more straightforward and cost-effective process compared to veneer.

3). Installation

3.1 Installation of veneer

Installing the veneer involves a multi-step process. First, the substrate needs to be prepared by sanding it smooth and ensuring it is clean and free of any imperfections. Then, an adhesive is applied to both the substrate and the back of the veneer sheet. The veneer is carefully placed onto the substrate, and pressure is applied to ensure proper bonding. Finally, the excess veneer is trimmed off and the edges are sanded and finished. It is crucial to handle the veneer with care during installation to prevent damage.

3.2 Installation of MDF

MDF is a manufactured wood product made from compressed wood fibers. It is often used as a substrate for veneer because of its smooth and consistent surface. Installing MDF involves cutting the panels to the desired size and shape using appropriate tools. The panels can then be joined together using screws, nails, or adhesive.

MDF is relatively easy to work with due to its uniformity and stability. However, it is important to wear appropriate protective equipment when cutting or sanding MDF as it produces fine dust particles that can be harmful if inhaled.

4). Strength and Durability

4.1 Strength and Durability of Veneer

The strength and durability of the veneer largely depend on the quality of the wood veneer and the substrate used. High-quality veneer with a thick layer of wood can provide excellent strength and durability.

In terms of strength, the veneer can be quite strong and resistant to warping or cracking when properly applied. It has the advantage of utilizing the natural strength properties of the wood species it is made from. Hardwood veneers, such as oak or walnut, tend to be more durable than softwood veneers like pine. However, the thickness of the veneer layer also plays a role in its strength. Thicker veneers are generally more durable and less susceptible to damage.

When it comes to durability, veneers can be highly durable if properly cared for. It can withstand regular use and resist scratches, stains, and fading. However, since it is a thin layer of wood, it is more susceptible to damage from moisture, heat, and direct impact.

Veneer offers strength and durability by utilizing the natural properties of real wood. The quality of the veneer and substrate used plays a significant role in its strength and durability. The veneer can be strong and resistant to warping when properly applied, but it may be more susceptible to damage from moisture, heat, and impact.

It is important to protect veneered surfaces from excessive exposure to water and heat sources to maintain their durability.

4.2 Strength and Durability of MDF

MDF is known for its uniform density and smooth surface, making it an ideal substrate for veneer. However, MDF is not as strong as solid wood or plywood. It can be prone to sagging or breaking under heavy loads or stress. While MDF is reasonably strong for most furniture and cabinetry applications, it may not be suitable for heavy-duty or high-impact usage.

It is less prone to warping or expanding and contracting with changes in temperature and humidity compared to solid wood. MDF also has good resistance to scratches and dents, making it suitable for high-traffic areas or environments where impact resistance is important. However, it is worth noting that MDF can be susceptible to moisture damage. If exposed to prolonged moisture or standing water, MDF can swell and lose its structural integrity.

MDF has good resistance to scratches and dents, but it may not be as strong as solid wood or plywood. While MDF is less susceptible to warping or expanding and contracting with humidity changes, it can be vulnerable to moisture damage if not properly protected.

Ultimately, the choice between veneer and MDF depends on the specific requirements of your project, such as budget, aesthetic preferences, and usage conditions. Consider consulting with a professional or experienced woodworker to determine the most suitable option for your needs

5). Maintenance

5.1 Maintenance of Veneer

- The veneer requires regular cleaning with a soft cloth or microfiber cloth to remove dust and dirt.

- It is important to avoid using abrasive cleaners or harsh chemicals that can damage the veneer surface.

- The veneer should be protected from excessive moisture and direct sunlight to prevent warping or fading.

- If the veneer gets scratched or damaged, it can be repaired by refinishing or reapplying a new layer of veneer.

5.2 Maintenance of MDF

- MDF is a manufactured wood product and has a smooth, consistent surface that is easy to clean.

- It can be wiped down with a damp cloth or mild soapy water to remove stains or spills.

- Avoid using excessive water as MDF is not moisture-resistant and can swell or warp.

- MDF is more prone to scratches and dents compared to veneer, so it is important to handle it with care and use protective pads or coasters for objects placed on it.

- If the MDF gets damaged, it is difficult to repair, and the best solution may be to replace the affected piece.

In summary, veneer requires regular dusting and gentle cleaning, while MDF is easy to clean but more susceptible to scratches and dents. The veneer can be refinished if damaged, while MDF may need to be replaced.

6). Cost Comparison

The cost of veneer and MDF (Medium Density Fiberboard) can vary depending on several factors such as the quality of the materials, the thickness of the veneer, and the size of the project.

Veneer prices can range widely based on the type of wood used, the thickness of the veneer, and the quality of the product. Generally, the veneer can be more expensive than MDF.

While MDF, being an engineered wood product, is typically less expensive than veneer, depending on the thickness and quality of the board.

7). Difference between Veneer and MDF

|

S.No. |

Veneer |

MDF |

|

1. |

Veneer is a thin layer of real wood |

MDF is an engineered wood product made by compressing wood fibers with a resin binder. |

|

2. |

Veneer provides the natural and authentic look of real wood grain |

While MDF lacks the natural grain patterns found in veneer. |

|

3. |

It can showcase the unique patterns and textures of different wood species. |

MDF has a uniform and smooth surface |

|

4. |

Veneer is less durable and its durability can vary depending on the quality and thickness of the veneer. |

MDF is generally more durable and resistant to warping or splitting compared to veneer. |

|

5. |

Veneer tends to be more expensive than MDF because it utilizes real wood |

MDF is generally more affordable since it is a manufactured wood product. |

|

6. |

The veneer can be used to cover a variety of surfaces, such as furniture, cabinetry, doors, and decorative panels, to provide an attractive wood finish. |

MDF is often used for its smooth and consistent surface, making it suitable for painting, laminating, or veneering. |

|

7. |

Veneer offers the beauty and authenticity of real wood |

While MDF provides stability, versatility, and affordability. |

8). Conclusion

In summary, the veneer is a good choice if you want the aesthetic appeal of wood at a lower cost, but it may require more maintenance. MDF is a versatile and affordable option, but it lacks the strength and natural beauty of solid wood or veneer. The choice between the two ultimately depends on your specific needs, budget, and desired aesthetic. The veneer can be used to cover a variety of surfaces, such as furniture, cabinetry, doors, and decorative panels, to provide an attractive wood finish. MDF is often used for its smooth and consistent surface, making it suitable for painting, laminating, or veneering.

A veneer can be used to cover a variety of surfaces, such as furniture, cabinetry, doors, and decorative panels, to provide an attractive wood finish. MDF is often used for its smooth and consistent surface, making it suitable for painting, laminating, or veneering. MDF does not have a natural grain like wood, but it can be easily painted or veneered to achieve the desired look. However, it is not as strong as solid wood and can be prone to moisture damage if not properly sealed.

So friends this was the basic comparison between Veneer V/s MDF. I hope this article will definitely help you. If you like this information please share it with your friends & If I have missed any information or you have any suggestions then you can mention them in the comments section for more such blog posts just click subscribe to myengineeringsupport.com so that you won’t miss any new post.

If you want a PDF copy of this,

So let’s know by commenting & you can message us on our Instagram & telegram channel, or you can download it from the top right-hand corner of this post.

Bar Bending Schedule (BBS) Basics Part -1

This Ebook is specially designed for Freshers Civil Engineers. Recommended for Quantity Surveyors & Billing Engineers. Here You Can Learn All Basic Concepts & Formulas for Bar Bending schedules (BBS).

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning

Also, Read,

Wall Mounted vs Floor Mounted Toilets

Flush Door vs Wooden Panel Door

concealed wiring and open wiring

UPVC vs Aluminium vs Wooden Windows

Gypsum Plaster vs Cement Plaster

Related Video,