Welcome to our comprehensive guide on using chicken mesh for plastering in India. Chicken mesh is an essential component in the plastering process, offering a range of benefits that can enhance the durability and stability of your projects. In this guide, we will explore the various aspects of chicken mesh for plastering, including its different types, uses, advantages, and practical applications.

Key Takeaways:

- Chicken mesh is a crucial component in plastering projects in India.

- This guide provides a comprehensive understanding of the different types of chicken mesh For Plastering, their uses, and their advantages.

- Choosing the right type and thickness of chicken mesh is vital for achieving optimal plastering results.

- Common names for chicken mesh in the Indian market and its practical applications in plastering projects are discussed.

- With this knowledge, you can make informed decisions when incorporating chicken mesh for your plastering projects in India.

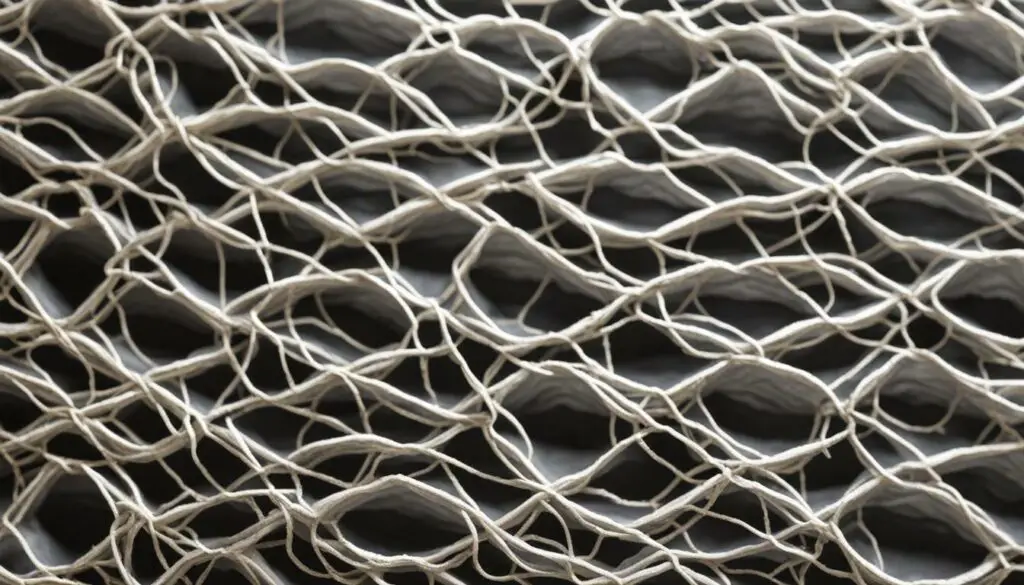

What is Chicken Mesh?

Before we dive into the details of using chicken mesh for plastering, let’s start by understanding what chicken mesh is and why it is called chicken mesh. Chicken mesh, also known as poultry netting, is a type of metal wire mesh that is commonly used in the agricultural industry to fence poultry and other small animals. The mesh is made of thin, flexible wires that are woven into a hexagonal pattern, resembling the shape of a honeycomb.

So why is it called chicken mesh? Well, the mesh was originally used to keep chickens and other small animals in their pens, hence the name “chicken mesh“.

Today, chicken mesh is used for a variety of purposes beyond just fencing. It is a popular material for plastering in India, where it is used to reinforce the plaster and prevent cracks from forming.

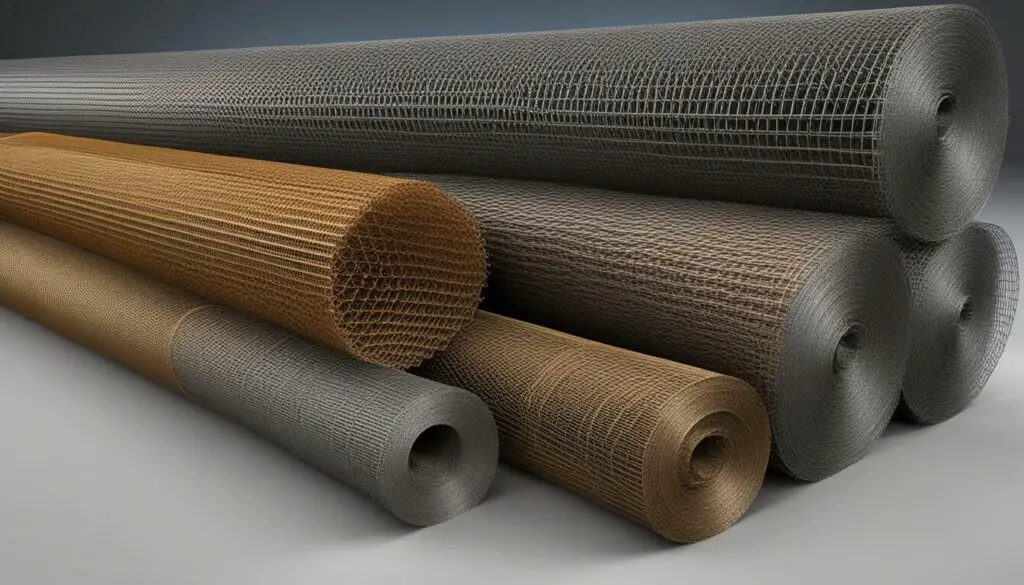

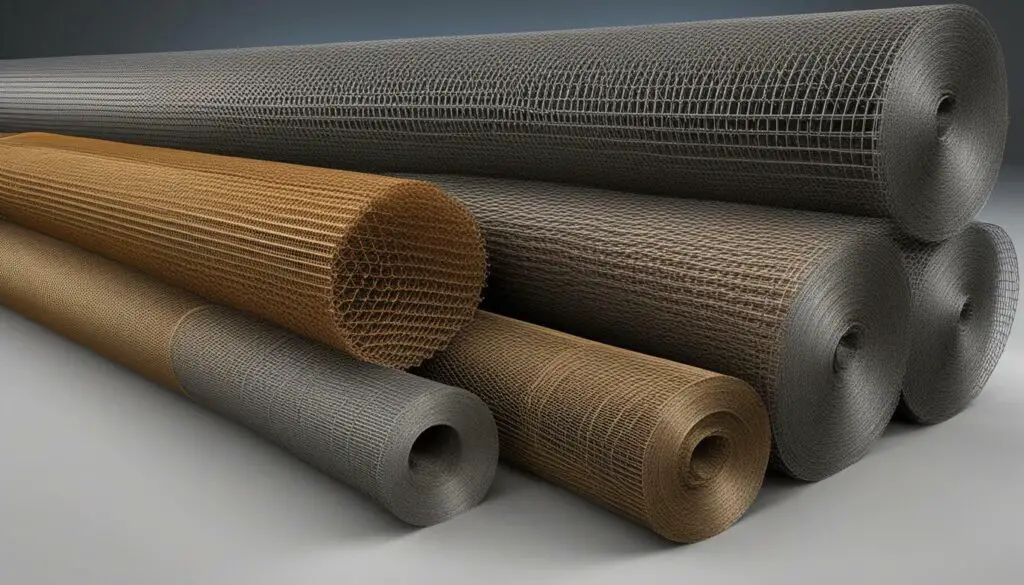

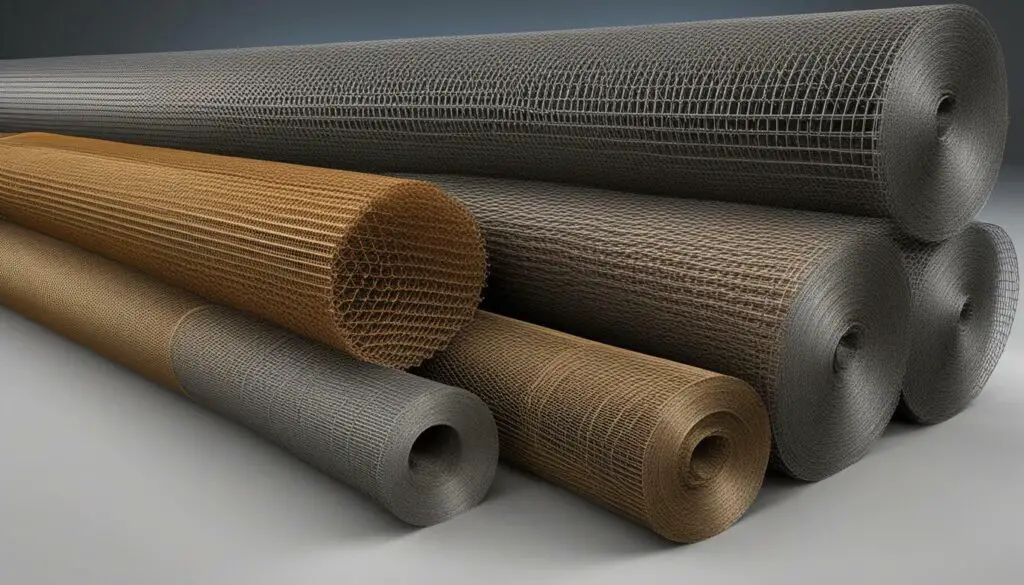

Different Types of Chicken Mesh For Plastering

When it comes to plastering, there are different types of chicken mesh available. Each type varies in terms of material, properties, and usage. Here are the three most commonly used types of chicken mesh:

| Type of Chicken Mesh | Material | Properties |

|---|---|---|

| Fiberglass Mesh | Fiberglass | Resistant to alkalis, high tensile strength, lightweight, easy to cut, and low cost. |

| Aluminum Mesh | Aluminum | Lightweight, durable, corrosion-resistant, and flexible. |

| Stainless Steel Mesh | Stainless Steel | High tensile strength, durable, corrosion-resistant, and suitable for heavy-duty applications. |

It’s important to note that each type of chicken mesh has its own set of advantages and disadvantages, and the choice of mesh should be based on the specific requirements of the plastering project.

Now that you understand the different types of chicken mesh available, let’s move on to exploring their uses in plastering.

Uses of Chicken Mesh For Plastering

Chicken mesh is widely used in plastering for various purposes. Its key advantage is that it strengthens the plaster, preventing cracks and providing structural stability to the surface. Here are some of the main uses of chicken mesh in plastering:

- Strengthening the plaster: Chicken mesh helps strengthen the plaster by providing a foundation for the plaster to adhere to. This is particularly useful for surfaces that are uneven or prone to cracking.

- Preventing cracks: Chicken mesh helps prevent cracks from forming on plastered surfaces. The mesh reinforces the plaster and helps distribute stress evenly across the surface, reducing the risk of cracks.

- Structural stability: Chicken mesh provides added structural stability to plastered surfaces. It helps distribute weight evenly across the surface, reducing the risk of sagging or collapsing.

- Bridging gaps: Chicken mesh can be used to bridge gaps in the surface being plastered, such as small holes or gaps in the wall. This creates a smooth and even surface for the plaster to adhere to.

- Flexibility: Chicken mesh is flexible and can be easily shaped to fit the required surface. This makes it ideal for use on curved or irregular surfaces.

Overall, chicken mesh is a versatile material that can be used in a range of plastering projects. Its ability to improve the strength, stability, and durability of plastered surfaces makes it an essential tool for any plastering job.

Advantages of Using Chicken Mesh For Plastering

Using chicken mesh in plastering offers numerous benefits for both internal and external applications. Here are some of the advantages:

| Advantages | Description |

|---|---|

| Enhanced Durability | The use of chicken mesh in plastering ensures that the plaster is stronger and more durable, ensuring longevity. |

| Prevents Cracks | Chicken mesh helps prevent cracks from forming in plastered surfaces by providing a reinforcing layer that absorbs stress and prevents the plaster from expanding and contracting. |

| Structural Stability | Chicken mesh adds structural stability to walls and ceilings, reducing the risk of damage caused by external factors such as wind, rain, and seismic activity. |

| Flexibility | Chicken mesh is a flexible material that can be easily shaped to fit any surface, making it a versatile option for various plastering projects. |

| Uniformity | The use of chicken mesh ensures that the plaster is evenly distributed, resulting in a smoother and more uniform surface. |

Overall, using chicken mesh in plastering offers numerous benefits, making it a popular choice for both DIY enthusiasts and professional contractors alike.

Best Chicken Mesh for Plastering – Internal and External

When it comes to choosing the best chicken mesh for plastering, it’s essential to consider the specific requirements of your project. Not all chicken mesh types are suitable for both internal and external applications, so it’s crucial to choose the right one.

Fiberglass mesh is a popular choice for internal plastering due to its flexibility and ease of handling. It is also an affordable option that provides excellent structural support to the plaster. On the other hand, Aluminum mesh is best suited for external plastering projects as it has excellent weather resistance and can withstand harsh weather conditions. It offers unparalleled protection against moisture and is also structurally strong.

Stainless steel mesh is another option for external plastering projects, especially those that require additional strength and durability. It is resistant to corrosion and can withstand heavy impacts, making it an ideal choice for areas that are exposed to potential damage.

Ultimately, the best chicken mesh for plastering internal and external projects depends on various factors such as the climate, the project’s location, and the strength and durability required.

Chicken Mesh Thickness and Size

The chicken mesh comes in a variety of thicknesses and sizes, which can impact its effectiveness in plastering projects. Choosing the appropriate thickness and size for your specific project is crucial to ensure successful results.

The thickness of chicken mesh is measured in gauges, with a higher gauge indicating a thinner mesh. The most common gauges available for chicken mesh in India range from 18 to 22. For plastering purposes, we recommend using chicken mesh with a gauge of 20. This thickness provides sufficient strength and durability for most internal and external plastering projects.

When it comes to size, chicken mesh can vary in width and length. The most common widths for chicken mesh are 0.5 meters and 1 meter, while lengths can range from 10 meters to 50 meters. The size you choose will depend on the size of your project. However, it is important to note that larger mesh sizes can result in a more challenging installation process.

In summary, the optimal thickness and size of chicken mesh for plastering projects in India is 20 gauge with a width of either 0.5 meters or 1 meter and a length suitable for the project at hand. By choosing the appropriate thickness and size of chicken mesh, you can ensure the success of your plastering project and achieve the desired result.

Chicken Mesh for Plastering: Practical Applications

Chicken mesh is a versatile material that can be used in various plastering applications. Depending on your specific needs, different types of chicken mesh offer specific advantages. Here we will explore the practical applications of different chicken mesh types, including fiberglass mesh, aluminum mesh, and stainless steel mesh.

Fiberglass Mesh with Uses

Fiberglass mesh is a popular type of chicken mesh used in internal plastering. It is lightweight, easy to handle, and has excellent flexibility, making it ideal for curved surfaces. Additionally, fiberglass mesh is resistant to alkali and corrosion, making it a durable choice for long-term projects.

The uses of fiberglass mesh in plastering include:

- Reinforcing plaster surfaces

- Preventing cracks from forming in plaster

- Improving the overall durability of plaster surfaces

Aluminum Mesh with Uses

Aluminum mesh is commonly used in external plastering applications. It is corrosion-resistant and can withstand extreme weather conditions, making it a reliable choice for outdoor projects. Additionally, aluminum mesh is known for its strength, making it effective in further stabilizing plaster surfaces.

The uses of aluminum mesh in plastering include:

- Providing structural stability to plaster surfaces

- Preventing cracks from forming in plaster due to changes in temperature and weather conditions

- Enhancing the overall strength of plaster surfaces in high-stress areas

Stainless Steel Mesh with Uses

Stainless steel mesh is a heavy-duty chicken mesh used in projects that require maximum strength and durability. It is resistant to corrosion and can withstand extreme weather conditions, making it ideal for both internal and external plastering applications. Additionally, stainless steel mesh is highly stable and can effectively provide structural support to plaster surfaces.

The uses of stainless steel mesh in plastering include:

- Providing maximum reinforcement to plaster surfaces

- Preventing cracks from forming in plaster due to high-stress areas or extreme weather conditions

- Offering additional support to plaster surfaces in high-traffic areas

By understanding the specific uses and advantages of different types of chicken mesh, you can choose the right material for your plastering project. Whether you need fiberglass mesh for internal surfaces or stainless steel mesh for heavy-duty applications, chicken mesh can provide the reinforcement and durability needed for a successful plastering project.

Chicken Mesh: A Versatile Solution for Plastering in India

Chicken mesh is a widely used material for plastering in India, known by various names such as chicken wire mesh, plaster mesh, and poultry netting. It is a flexible and durable mesh made of galvanized iron wire, which provides structural stability and prevents plaster from cracking or crumbling. Thanks to its versatility, the chicken mesh can be used for both internal and external plastering applications.

One of the major advantages of chicken mesh is its ability to reinforce the plaster and increase its lifespan. Its diamond-shaped pattern creates a strong grip on the plaster, which prevents it from detaching or loosening over time. Additionally, chicken mesh is highly resistant to corrosion and weathering, allowing it to withstand harsh climates and temperatures.

Another benefit of using chicken mesh is its flexibility. The mesh can be easily cut and bent to fit any shape or size of the surface that needs plastering. This makes it a popular choice for irregular surfaces or structures, such as arches, domes, and columns.

Moreover, chicken mesh is available in different types, each with its unique properties and advantages. The most common types of chicken mesh used in plastering include fiberglass mesh, aluminum mesh, and stainless steel mesh. Fiberglass mesh is lightweight and easy to handle, while aluminum mesh is highly resistant to rust and corrosion. Stainless steel mesh, on the other hand, is the most durable and long-lasting option, making it suitable for high-traffic areas or heavy-duty applications.

| Type of Chicken Mesh | Advantages |

|---|---|

| Fiberglass Mesh | Lightweight and easy to handle |

| Aluminum Mesh | Highly resistant to rust and corrosion |

| Stainless Steel Mesh | The most durable and long-lasting option |

When selecting the best chicken mesh for plastering, it is important to consider factors such as weather resistance, strength, and size. The right chicken mesh can enhance the overall quality of your plastering project and provide long-lasting results.

In conclusion, chicken mesh is a versatile and reliable solution for plastering in India. Its multiple advantages and practical applications make it a popular choice among contractors and builders. By understanding the different types, uses, and advantages of chicken mesh, you can make informed decisions when incorporating it into your plastering projects.

Conclusion

In conclusion, we hope this guide has provided you with a comprehensive understanding of chicken mesh for plastering in India. Whether you are a professional contractor or a DIY enthusiast, incorporating chicken mesh in your plastering projects can enhance durability, prevent cracks, and provide structural stability.

We have explored the different types of chicken mesh available, including fiberglass mesh, aluminum mesh, and stainless steel mesh, and discussed their unique properties and advantages. We have also highlighted the best types of chicken mesh for internal and external plastering applications.

It is essential to consider the thickness and size of the chicken mesh for optimal effectiveness in plastering projects. By using the right chicken mesh for plastering, you can ensure a reliable and long-lasting finish.

Chicken mesh offers practical applications in various plastering scenarios, and its popularity in the Indian market makes it a versatile solution for plastering. Knowing the common names used for chicken mesh in India can help you find the right product for your projects.

Make Informed Decisions

Armed with this knowledge, we urge you to make informed decisions when incorporating chicken mesh into your plastering projects in India. Understanding the uses and advantages of chicken mesh can help you achieve a high-quality plastering finish that stands the test of time.

Happy Learning

Also, Read,