Compound wall cost per Rft & Sqft in India

Today we will estimate the cost of boundary wall construction in India, So let’s start…..

Compound wall cost per Rft & Sqft

Given Data,

Size of Plot – 40′ x 30′

Column-to-column distance – 10ft.c/c

Main Gate size – 10′

Pcc thickness – 4”

Pcc Grade – M15 (1:2:4)

Footing Size – 1.5′ x 1.5′

Footing height below GL – 2.5′

Steel bar diameter in footing – 10mm

Plinth beam size – 9” x 12”

Plinth beam depth below GL with PCC – 7” + 4″ = 11”

Plinth beam depth above GL – 5”

Column size – 9” x 9”

Height of Boundry wall from GL – 6 feet

wall thickness – 6”

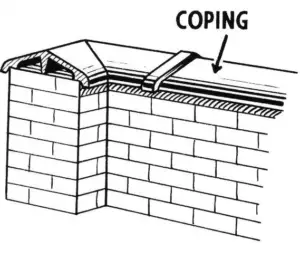

Coping thickness – 4”

The thickness of rubble soling – 9” or 0.75′

No. of Column required in total Compound wall

Site perimeter/c/c column distance

Site perimeter – Length of wall 1 + Length of wall 2 + Length of wall 3 + Length of wall 4

= 40 + 40 + 30 + 30 – 140feet

So, Total no. of column = 140/10 = 14Nos.

Step no.1 – Excavation quantity

i). Earthwork Excavation

Size of footing – 1.5′ x 1.5′

Excavation on both sides – 3”

So, the Excavation size of the footing will be – 2′ x 2′

Footing height below GL – 2.5′

Then, the total volume of footing excavation – footing length x footing breath x footing depth (l x b x h)

– 2′ x 2′ x 2.5′ = 10cft

and, total no. of column footing – 14Nos.

So, total the total volume of footing excavation – (footing excavation volume x no. of footing)

– 10 x 14 = 140cft

ii). Plinth Beam Excavation

Plinth beam size – 9” x 12”(LxD)

Let’s take both side offset for excavation of beam – 4”

So, Width of plinth beam – 9″ + 4″ + 4″ =17″ or 1.416ft

Plinth beam depth below GL with PCC – 7” + 4″ = 11” or 0.9166′

Plinth beam depth above GL – 5”

Then, the total volume of excavation – Perimeter of the site – (No. of footing x footing width) x plinth beam excavation width x plinth beam excavation depth

= 140 – (14 x 2′) x 1.416 x 0.9166 (depth below GL)

= 112 x 1.416 x 0.9166 = 145.365Cft

The total volume of excavation for the compound wall

= footing excavation + Plinth beam excavation – 140 + 145.365 = 285.365Cft

Step no.2 – Rubble Soling (only in Footing)

The thickness of rubble soling – 9” or 0.75′

Size of footing – 2′ x 2′

Depth of soling – 0.75′

No. of footing – 14Nos.

So, The volume of soling in footing – Footing area x depth of soling x no. of footing

= 2′ x 2′ x 0.75′ x 14 = 42Cft.

Step no.3 – PCC Quantity

i). PCC for footing

Pcc thickness – 4” or 0.33′

No. of footing – 14Nos.

Length of footing – 2′

Width of footing – 2′

The volume of Pcc in footing – l x b x h x No. of footing

– 2′ x 2′ x 0.33′ x 14 = 18.48Cft

ii). PCC for plinth beam

The volume of excavation of beam – 145.365Cft

Pcc thickness – 4” or 0.33′

Plinth beam depth below GL with PCC – 7” + 4″ = 11” or 0.9166′

The volume of PCC for plinth beam – by volume ratio with plinth beam excavation

= (0.33/0.9166) x 145.365 = 0.36 x 145.365 = 52.33Cft

So, The volume of PCC for compound wall – Pcc volume of footing + PCC volume of plinth beam

=18.48 + 52.33 = 70.81Cft.

Step no.4 – Materials Calculation PCC Quantity

Given, Pcc Grade – M15 (1:2:4)

The total volume of PCC – 70.81Cft.

First of all, for easy calculation, we will convert Pcc quantity Cft to Cum

To convert Cft to Cum → Multiply by 0.02831 or divide by 35.31

(Because 1Cft = 0.02831Cum)

So, the volume of PCC – 70.81Cft x 0.02831 = 2.004Cum

but it is the wet volume of concrete & to calculate qty of materials first we calculate the dry volume of PCC

Always, remember one thing,

The dry volume of concrete is always 54% more than the wet concrete

So, the dry volume of PCC = 2.004 x 54% = 3.086Cum.

Now, we will calculate the Qty of materials for PCC

i). Cement Quantity

Formula = Volume of dry concrete/Sum of Ratio x Cement ratio in the mix

= 3.086/(1+2+4) x 1 =0.441Cum

As you know, the density of cement = 1440Kg/m³

Volume of cement in kg = 0.441 x 1440 = 635.04kg

As we all know, 1 cement bag = 50kg

Number of cement bags = 635.04/50 = 12.70Bags

ii). Sand Quantity

Formula = Volume of dry concrete/Sum of Ratio x Sand ratio in the mix

= 3.086/(1+2+4) x 2 =0.8817Cum

To convert the quantity in Cft, multiply by 35.3147 (because 1cum is equal to 35.3147cft)

So, volume of sand = 0.8817 x 35.3147 = 31.22Cft

iii). Aggregates Quantity

Formula = Volume of dry concrete/Sum of Ratio x aggregates ratio in the mix

= 3.086/(1+2+4) x 4 = 1.7634Cum

To convert the quantity in Cft, multiply by 35.3147 (because 1cum is equal to 35.3147cft)

So, volume of sand = 1.7634 x 35.3147 = 62.274Cft

Step no.5 – Concrete quantity

i). Concrete volume for footing

Length of footing – 1.5′

Width of footing – 1.5′

The thickness of footing – 0.833

No. of footing – 14Nos.

The volume of footing concrete – L x B x H x no. of footing

– 1.5′ x 1.5′ x 0.833′ x 14 = 26.24cft or 0.743cum

ii). Concrete volume for Plinth beam

The total length of the perimeter is 140′

Width of plinth beam – 9”(0.75′)

Depth of plinth beam – 12”(1′)

Total column footing volume = Column width x Mno. of column

= 0.75′ (9”) x 14 = 10.5cft

So, the Volume of concrete in the plinth beam = Perimeter length x breadth x depth of plinth beam – Deduction of the volume of column footing

= (140 x0.75 x 1) – 10.5 = 94.5cft

iii). Concrete volume for Column

Column size – 9” x 9”(228mm x 228mm) or 0.75′ x 0.75′

Column height above GL – 6.416ft

Column height below GL – 7” (0.583′)

No. of column = 14Nos.

The volume of concrete in column = l x b x h x no. of column

L x B x (Column height below GL + Column height above GL) x no. of column

= 0.75 x 0.75 x (6.416 + 0.583) x 14 = 0.75 x 0.75 x 7 x 14 = 55.125Cft or 1.561Cum.

Step no.6 – Steel quantity

i). Quantity of steel in footing

Length of footing – 1.5′

The breadth of footing – 1.5′

A number of footing – 14Nos.

Footing thickness – 0.833′

if we consider,

Steel bar diameter in footing – 10mm

Spacing – 5”

Clear cover – 2”

So, the total steel qty of footing = 43.98kg.

ii). Quantity of steel in Plinth beam

Perimeter length of beam – 140′ or 42672mm

Plinth beam size – 9” x 12”

if we consider,

Steel main bar diameter – 12mm@ 4Nos. (2top, 2bottom)

Stirrups – 8mm@150mm c/c spacing

Clear cover – 25mm (for all sides)

So, the total steel qty of the plinth beam with stirrups & 2%wastage will be = 260.69kg.

iii). Quantity of steel in Column

Column size = 9” x 9”

Total no. of column = 14nos.

if we consider,

Longitudinal bar diameter – 12mm@ 4Nos.

Stirrups – 6mm@150mm c/c spacing

Clear cover – 40mm

So, the total steel qty of the column with stirrups & 5%wastage will be = 12.564 x 14 = 175.9kg.

The total weight of steel for the compound wall

= footing steel qty + Plinth beam steel qty + Column steel qty – 43.98 + 260.69 + 175.9 = 480.57Kg

Step no.7 – Brick & Block masonry quantity

The total length of the compound wall = site perimeter – main gate length

= ( 40′ x 2nos.) + (30′ x 2nos) – 10′

= 80′ = 60′ – 10′ = 130feet

The total length of block masonry – compound wall length – (no. of column x width of a single column)

= 130′ – ( 14nos – 0.75′) = 130′ – 10.5′ = 119.5′

Height of boundary wall = compound wall height – coping thickness

= 6′ – 4”(0.33′) = 5.67′

The volume of block masonry = l x h x thickness of the wall

= 119.5 x 5.67 x 0.6(0.5′) = 338.7825cft or 9.593Cum

Brick standard size = 190 x 90 x90mm

No. of red bricks required = 4794Nos.

Cement required in brick masonry – 12Nos.

Sand required in brick masonry – 88.99Cft

No. of concrete blocks required = 712Nos.

Cement required in block masonry – 3.516bags

Sand required in sand masonry – 25.86Cft

Step no.8 – Coping concrete quantity

Coping thickness – 4” (0.33′)

Concrete grade – M15

= Volume – coping length x width x thickness

= Brick masonry length x masonry width x coping thickness

= 119.5′ x 0.5′ x 0.33′ = 19.717Cft or 0.558Cum.

if we consider M15 concrete grade for coping

So, cement required = 3.537bags

Sand required – 8.675cft

Aggregates required – 17.35cft

Step no.9 – Backfilling quantity

i). For Footing – 48.69cft

ii). For plinth beam – 36.412cft

The total volume of backfilling – 48.69 + 36.412 = 85.102cft or 2.409cum.

ESTIMATE OF BOUNDARY WALL

Total Concrete Volume – Footing + Plinth beam + Column

= 0.743 + 2.675 + 1.561 = 4.979m³ or 175.83Cft

For M20 Concrete Grade –

Cement Required – 40Bags

Sand Required – 2.091m³ or 73.85Cft

Aggregates Required – 4.182m³ or 147.68Cft

Total Materials qty required for compound walls

i). Total no. of cement required – Pcc + Masonary + RCC + Coping

= 12.70 + 12 + 40 + 3.537 = 68.237Bags

ii). Total volume of Sand required – Pcc + Masonary + RCC + Coping

= 31.22 + 88.99 + 73.85 + 8.675 = 202.735Cft

iii). Total volume of Aggregates required – Pcc + Masonary + RCC + Coping

= 62.30 + 147.68 + 17.35 = 227.33Cft

iv). Total steel required – Footing + plinth beam + column

= 43.98 + 260.69 + 175.9 = 480.57kg

v). Boulder for soling – 42Cft

vi). Bricks – 4794Nos.

Materials & Labor cost of boundary walls

Materials Cost

i). Boulder soling qty – 42cft.

Market Rate – 28/-Cft

Total Amount = 42 x 28 = Rs.1176/-

ii). Cement bag – 68.237Bags

Market Rate – 400/- bags (ultra-tech, Ambuja, acc)

Total Amount = 68.237 x 400 = Rs.27,295/-

iii). Sand qty – 202.735

Market Rate – 60/-Cft

Total Amount = 202.735 x 60 = Rs.12164/-

iv). Aggregates qty – 227.33

Market Rate – 55/-Cft

Total Amount = 227.33 x 55 = Rs.12503/-

v). Red Brick’s qty – 4794Nos.

Market Rate – 8/-nos.

Total Amount = 4794 x 8 = Rs.38352/-

vi). Steel qty – 480.57kg

Market Rate – 100/-kg.

Total Amount = 480.57 x 100 = Rs.48057/-

Total Materials Cost – Boilder soling qty + Cement bag + Sand qty + Aggregates qty + Red Brick’s qty + Steel qty

= 1176 + 27295 + 12164 + 12503 + 38352 + 48057 = Rs.1,39547/-

Labor Cost

i). Excavation qty – 285.365cft

Labor Rate – 7/-Cft

Total Amount = 285.365 x 7 = Rs.1998/-

ii). Boilder soling qty – 42cft

Labor Rate – 8/-Cft

Total Amount = 42 x 8 = Rs.336/-

iii). PCC work qty – 70.81cft

Labor Rate – 25/-Cft

Total Amount = 70.81 x 25 = Rs.1770/-

iv). Backfilling work qty – 85.102cft

Labor Rate – 5/-Cft

Total Amount = 85.102 x 5 = Rs.425/-

v). Rcc work qty – 175.83cft

Labor Rate – 65/-Cft

Total Amount = 175.83 x 65 = Rs.11429/-

vi). Brick masonry work – 338.78cft

Labor Rate – 25/-Cft

Total Amount = 338.78 x 25 = Rs.8470/-

vii). Coping work qty – 19.717cft

Labor Rate – 35/-Cft

Total Amount = 19.717 x 35 = Rs.690/-

Total Labor Cost – Excavation + Boilder soling qty + PCC work + Backfilling work + Rcc work + Brick masonry work + Coping work

= 1998 + 336 + 1770 + 425 + 11429 + 8470 + 690 = Rs.25,118/-

Total Cost (Materials + labor) = 1,39547 + 25118 = Rs.1,64665/-

Add 1.5% water & labor charge for curing – Rs.2470/-

Add contractor profit 10% – Rs.16,466/-

So, Total cost of Boundary Wall – Rs.1,64665 + 2470 + 16,466 = Rs.1,83601/-

Compound wall cost per Rft = Total cost / Wall length

= 183601/140 = Rs.1311/-Rft

Compound wall cost per Sqft = Cost per Rft / Wall height above GL

= 1311/6.416 = Rs.205/-Sqft

Thank you for taking the time to read this educational blog post about the Estimation of the Compound Wall. We hope that you found it informative and engaging. If you have any questions or comments, please feel free to leave comments in the comment section below. Don’t forget to check out our other educational posts on myengineeringsupport.com for more learning opportunities!

Bar Bending Schedule (BBS) Basics Part -1

This Ebook is specially designed for Freshers Civil Engineers. Recommended for Quantity Surveyors & Billing Engineers. Here You Can Learn All Basic Concepts & Formulas for Bar Bending schedules (BBS).

I hope this information can be useful for you guys.

If you like this article then please share it with your friends & also like our Facebook Page and join our Telegram Channel.

If you want a PDF copy of this, Do let’s know by commenting & you can message us on our Instagram & telegram channel, or you can download it from the top right-hand corner of this post.

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning

Also, Read,

28 Important Comparison between WPC and PVC Wall Panel

MDF VS Particle Board – 15 Important Differences

Flush Door vs Wooden Panel Door

UPVC vs Aluminium vs Wooden Windows

Thanks for magnificent information. What trips can you recommend in 2024? Astro tourism, eco diving, home swapping, train stations are the new food destinations,sports tourism, coolcationing, gig tripping, private group travel?