Compressive Strength Test of Concrete

The compressive strength test of concrete is an essential procedure that helps engineers and construction professionals evaluate the strength and durability of concrete structures. The test is commonly done on concrete cubes, using a compressive testing machine to determine the maximum compression load the cube can withstand before failing. The results of the test provide valuable information about the quality and Compressive Strength Test of Concrete and its suitability for specific construction applications.

Key Takeaways

- The compressive strength test of concrete is a vital procedure to evaluate the strength and durability of concrete structures.

- The test is typically done on concrete cubes, and the results provide valuable information about the quality and suitability of the concrete for specific construction applications.

- The cube test procedure involves casting concrete cubes, curing them under specific conditions, and testing their compressive strength using a testing machine.

- The results of the compressive strength test help engineers and construction professionals ensure the safety and performance of concrete structures.

- The test is conducted under relevant codes of practice or standards, and the results are interpreted based on the specified curing periods.

What is the Compressive Strength of Concrete?

The compressive strength of concrete refers to the ability of a concrete specimen to withstand axially directed compressive forces. It is one of the most important properties of concrete, as it helps to determine the suitability of concrete for its intended use and to ensure the safety and reliability of structures.

The compressive strength of concrete is typically measured in psi (pounds per square inch) or MPa (megapascals) and is influenced by various factors, including the mix design, curing conditions, and age of the concrete.

For a better understanding of the compressive strength of concrete, a comparison can be made by understanding that the compressive strength of concrete is like the blood pressure of the human body. Just as blood pressure is used to assess the health of a person, the compressive strength of concrete is used to assess the quality of concrete and its ability to withstand loads.

Purpose of the Compressive Strength Test

The compressive strength test of concrete serves a critical purpose in assessing the durability and quality of concrete structures. This test is conducted to measure the maximum load-bearing capacity of a concrete cube or cylinder, typically sampled from a construction site, and to determine the compressive strength of the concrete.

The compressive strength test helps establish the strength and stability of concrete structures against external stressors, such as weather conditions, natural calamities, and heavy loads. The test allows engineers to determine the load-carrying capacity of a structure, anticipate its longevity, and prevent any potential collapse or damage.

Moreover, the compressive strength test of concrete helps ensure that the concrete mix meets the requisite standards and specifications, as outlined by the relevant codes of practice or industry-specific regulations. This quality control measure is vital in construction projects, as it helps identify any defects or weaknesses in a batch of concrete, preventing costly and time-consuming repairs.

“The Compressive Strength Test of Concrete test is a necessary and valuable tool for engineers and construction professionals, as it helps safeguard the integrity and safety of concrete structures while ensuring compliance with industry standards and regulations.”

Compressive Strength Test Procedure

The compressive strength test of concrete involves a standard procedure that ensures uniformity and accuracy of results. The procedure includes the following steps:

Preparation of Test Specimens (Concrete Cubes)

The first step in the compressive strength test is to cast test specimens, typically, 150 mm cubes. The concrete cubes should be cast using a standard concrete mix design and carefully compacted to eliminate any voids. After casting, the cubes are marked with relevant information to identify them throughout the testing process.

Apparatus Required

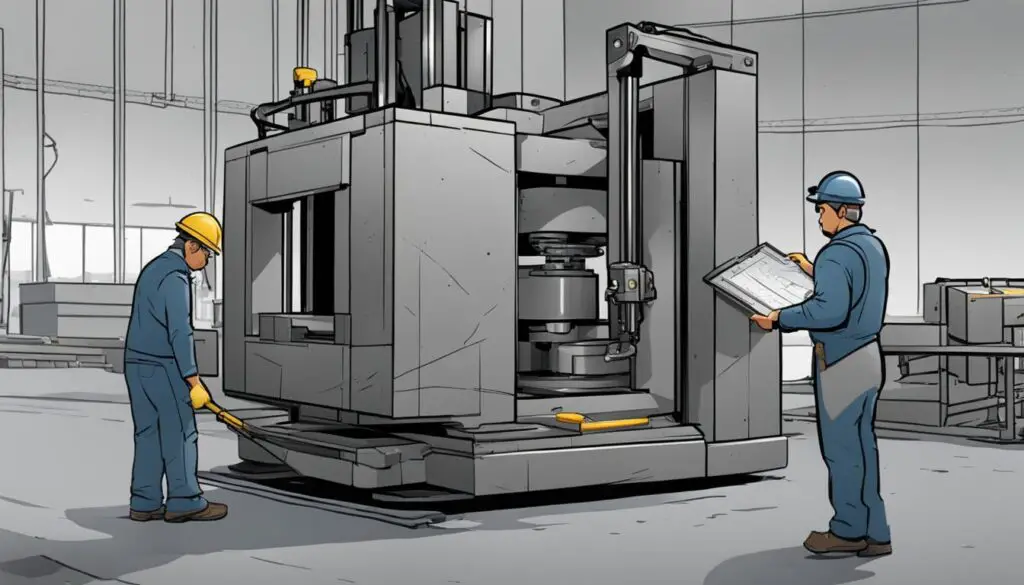

The following apparatus is required for conducting the compressive strength test:

- Curing Tank: A water tank to maintain a constant temperature and moisture level during the curing period.

- Compression Testing Machine: A machine with two platens for applying compressive force to the concrete cube specimens.

- Weighing Balance: A weighing balance to determine the weight of the concrete cubes.

Cube Casting Process

The casting process of the concrete cubes includes the following steps:

- Clean and oil the cube molds

- Mix the standard concrete test samples

- Pour the concrete mixture into the cube molds

- Smooth the top surface of the cubes using a trowel and allow any excess mix to overflow

- Label the cube mold with a unique identification number

- Cover the mold with a plastic sheet and allow it to set for 24 hours at room temperature

- After 24 hours, remove the cube from the mold and place it in the curing tank.

It is essential to ensure the concrete cubes are cured under standardized conditions to avoid any influence on the test results.

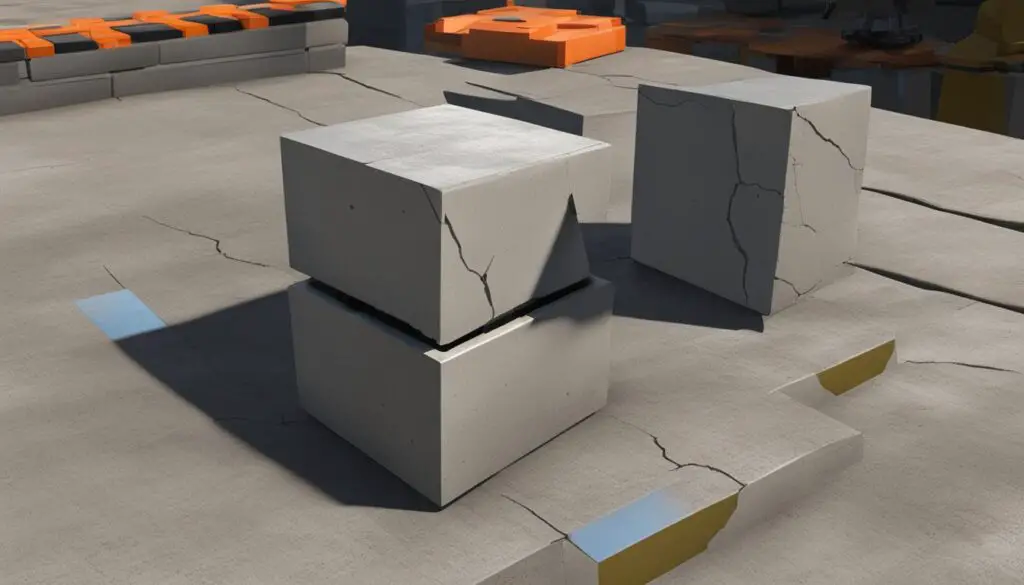

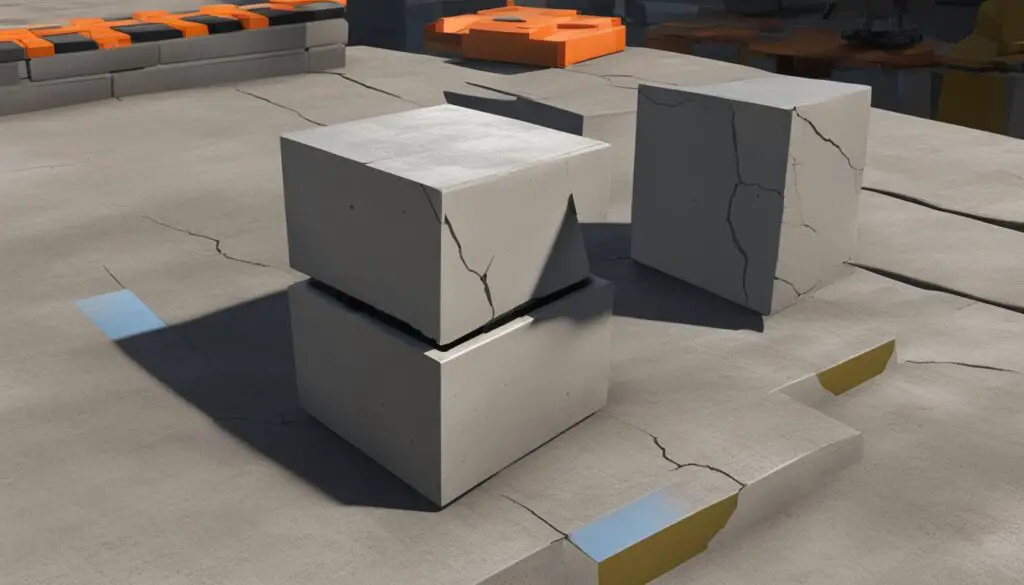

Note: For a visual representation of the apparatus required and the cube casting process, see the image below:

Number of Samples Required

To conduct a compressive strength test of concrete, a certain number of concrete cube samples are required. The number of samples needed may vary depending on the size and scope of the project, as well as the level of statistical significance desired.

Typically, for smaller projects or individual structures, a minimum of three concrete cube samples are recommended to be tested for compression strength, and the average of the test results is taken as the final result. However, for larger projects that require more precise and reliable results, additional samples may be needed.

It is important to note that when calculating the number of concrete cube samples required, various factors should be taken into consideration, including the design of the project, concrete mix proportions, curing conditions, and testing methods, to ensure the accuracy and validity of the test results.

Factors Affecting the Number of Samples

The number of concrete cube samples required for compressive strength testing can be influenced by a range of factors, including:

- The size and complexity of the project

- The desired level of accuracy and statistical confidence

- The mix design and concrete placement method

- The type and quality of testing equipment

- The environmental conditions during curing and testing

By taking into consideration these factors, as well as any project-specific requirements and standards, the number of concrete cube samples required for conducting a compressive strength test of concrete can be determined effectively, ensuring the reliability and safety of the final structure.

To summarize, it is essential to determine the appropriate number of concrete cube samples required for conducting a compressive strength test based on the specific characteristics and requirements of each project. By doing so, the accuracy and reliability of the test results can be ensured, providing valuable information for construction project management and maintenance.

Calculating the Compressive Strength of Concrete

After conducting the compressive strength test of concrete, the next step is to calculate the compressive strength value using the obtained test results. The formula for calculating compressive strength is:

| Parameter | Description |

|---|---|

| Fc | Compressive strength of concrete in pounds per square inch (psi) or megapascals (MPa) |

| Pmax | Maximum load applied to the specimen in pounds or newtons |

| A | The cross-sectional area of the specimen in square inches or square millimeters |

fc = Pmax / A

Once you have determined the value of Fc, you can compare it to the specified compressive strength requirements for your particular project. It is important to note that the compressive strength value is an average of the individual test results obtained from multiple cubes, and the number of samples required may vary depending on project specifications and statistical significance. The test results and calculated compressive strength value are crucial in evaluating the quality and safety of concrete structures.

Interpreting the Lab Report

After conducting a compressive strength test on concrete cubes, a lab report is generated. The report contains important information about the test results that can be used to evaluate the quality and strength of the concrete. It is crucial to understand how to interpret the lab report accurately.

“The lab report is a comprehensive summary of the test results showing the compressive strength and other relevant information such as curing age, weight, and dimensions of test specimens.”

The lab report typically includes the following details:

1. Compressive Strength Value

The compressive strength value is the primary result of the cube test. It indicates the maximum load that the concrete specimen can withstand before failure. The strength value is expressed in megapascals (MPa) and should be clearly stated in the report.

Compressive Strength Test of Concrete

2. Curing Age

The curing age refers to the number of days that the concrete cubes were kept under controlled curing conditions before testing. This information is crucial because it affects the rate of strength gain and can impact the final test results.

3. Weight

The weight of the concrete cubes is recorded before and after the compressive strength test to determine the density of the concrete. The weight measurements are also used to calculate the compressive strength value.

4. Dimensions of Test Specimens

The dimensions of the concrete cubes used for testing should be recorded in the lab report. This is important because it helps verify that the test specimens meet the required size specifications.

5. Other Relevant Information

The lab report may include additional relevant information, such as the date of test performance, the testing laboratory’s name and location, and the relevant code or standard used to perform the test.

When interpreting the lab report, it is crucial to pay attention to each piece of information to get a complete picture of the test results. The compressive strength value is the most critical factor, but other details such as curing age, weight, and dimensions of test specimens can provide valuable insights into the quality of the concrete.

Weighing the Concrete Cubes

Before and after conducting the compressive strength test, it is essential to weigh the concrete cubes accurately. The weight measurement is a crucial factor in determining the compressive strength of the concrete. It is important to note that using an incorrect weight value of the cube specimens can lead to inaccurate test results. Therefore, proper care should be taken while weighing the concrete cubes.

The weight of cast cubes should be taken immediately after the cube molds are removed. The wet cubes should be weighed within three minutes, to avoid evaporation of water. To obtain the dry weight, the wet cubes must be immersed in boiling water for five hours and then cooled in a desiccator before weighing.

The weight of all specimens should be recorded in grams. Any deviation in weight could lead to an error in calculating the compressive strength of the concrete. Thus, to obtain precise and reliable results, it’s important to ensure that the weighing machine is calibrated correctly and that any change in the atmosphere or humidity is considered before taking the reading.

“Accurate weight measurement is crucial to determining the compressive strength of concrete and ensuring the reliability of the test results.”

Concrete Cube Test Results – 7 Days as per IS Code

After conducting the compressive strength test of concrete cubes, the results are typically recorded at different curing periods such as 3, 7, and 28 days, as specified by the relevant code of practice. At the 7-day curing period, the compressive strength test results provide a preliminary indication of the concrete’s strength and can help adjust the project timeline and materials accordingly.

The concrete cube test results – 7 days as per IS code indicate the average compressive strength of concrete based on three samples. The code requires a minimum of three samples to be tested for each mix, and the results are recorded in megapascals (MPa) for easy comparison with the design strength specified in the project.

| Concrete Mix | Average Strength (MPa) |

|---|---|

| Mix Sample A | 20 |

| Mix Sample B | 25 |

| Mix Sample C | 30 |

The table above showcases the typical results of the compressive strength test of three concrete mixes during the 7-day curing period. Note that the results may vary depending on factors such as the curing conditions, specimen quality, and testing procedures. Therefore, it is essential to conduct the test following the relevant code of practice and taking care of the specified parameters for the concrete mix.

“The compressive strength test results at the 7-day curing period provide an early indication of the concrete’s performance and enable construction industry professionals to make timely decisions about the project timeline and resources.”

It is crucial to interpret the concrete cube test results with an element of caution, as these results may not represent the actual strength of the concrete structure over time, which is why the 28-day curing period is also critical for assessing the strength of the structure accurately. Nevertheless, the compressive strength test results – 7 days as per IS code provide valuable insights into the concrete’s early strength development and help optimize the curing process and project planning.

Concrete Cube Test Results – 28 Days as per IS Code

After the 28-day curing period, the concrete cubes are tested again for compressive strength to assess the long-term durability and performance of the concrete. As per the relevant IS code, the minimum average compressive strength of concrete that is expected from the samples should not be less than the characteristic strength plus 3 N/mm².

The test results obtained during the 28-day curing period are crucial in determining whether the concrete mix used in the construction project meets the required performance criteria. The compressive strength values obtained from the test allow engineers to assess the durability and longevity of concrete structures, and make necessary adjustments or corrective measures if needed.

It is essential to conduct the compressive strength test of concrete at both 7-day and 28-day curing periods to ensure that the concrete mix meets the minimum strength requirements, reduces the risk of structural failure, and ensures the safety and reliability of the built environment.

Comparison of Compressive Strength Test Results at 7 Days and 28 Days Curing Periods

| Curing Period | Number of Samples | Average Compressive Strength (N/mm²) | Minimum Compressive Strength (N/mm²) | Maximum Compressive Strength (N/mm²) |

|---|---|---|---|---|

| 7 days | 5 | 25 | 22 | 28 |

| 28 days | 5 | 45 | 42 | 48 |

Note: The table is for illustrative purposes only, and the values presented are not based on actual data.

Applicable Code for Concrete Cube Test

To ensure the accuracy and consistency of concrete cube test results, it is important to follow the relevant standard procedures. The Indian Standard (IS) code for concrete cube tests is IS 516:1959. This code outlines the detailed procedures and specifications for the test, including the casting of test specimens, conditions for curing and testing, and calculation of results.

Following the IS code for concrete cube tests ensures that the test is carried out in a reliable, consistent, and standardized manner. This enhances the quality and safety of concrete structures and ensures conformity with national and international standards.

It is important for engineers and contractors to be familiar with the IS code for concrete cube tests and to ensure that testing procedures are conducted under the code.

Importance of Compressive Strength Test

The compressive strength test of concrete is a crucial element in ensuring the safety, durability, and longevity of a concrete structure. The test determines the maximum load a concrete sample can bear before breaking, providing a measure of the concrete’s ability to resist compression. This information is critical for determining whether the concrete meets the required compressive strength for a specific construction project or application.

Additionally, the compressive strength test is an essential tool in quality control and construction project management. It allows for early detection of potential construction defects, such as inadequate mixing, curing, or improper detailing. Therefore, it is a vital component of ensuring the final structure meets all necessary specifications and standards.

The compressive strength test is invaluable in preventing engineering failures due to the inability of the structure to withstand the loads it is intended to bear. Without this critical test, the construction industry would be without the necessary information needed to ensure the safety and longevity of the structures being built.

Example:

The compressive strength test is paramount in ensuring the safety and longevity of a structure. The test enables engineers to evaluate the durability and strength of the concrete, allowing them to design properly and safely. Therefore, it is essential to conduct this test on every concrete mix before its use in any construction project.

Factors Affecting Compressive Strength

The compressive strength of concrete is influenced by several factors that can affect the quality of the final product. Understanding these factors is essential to ensure that the concrete meets the desired compressive strength and other specifications.

Factors that can affect the compressive strength of concrete include:

- The quality of raw materials used in the concrete mix, including cement, aggregates, water, and any adjuvants

- The mix design, including the proportion of raw materials and the specific concrete mix used in the construction process

- The curing conditions, including temperature, humidity, and duration of curing

- The testing procedure, including the accuracy of the testing equipment and the skill and training of the testing personnel

- The age of concrete, as the compressive strength of concrete typically increases with time

It is crucial to manage and control these factors during the concrete mixing, casting, and testing processes to ensure that the desired compressive strength levels are achieved. Careful monitoring and quality control processes can help to identify and address any issues that may affect the compressive strength of concrete during the construction process.

Variation in Compressive Strength Test Results

The compressive strength of concrete is a crucial parameter in determining the durability and performance of concrete structures. However, the results obtained from the compressive strength test can vary due to several factors. It is important to be aware of these factors to obtain accurate and reliable results.

One of the major factors that can affect the compressive strength test results is the preparation of the specimen. Any variations in the shape, size, and surface texture of the specimen can result in variations in the test results. The curing conditions, such as temperature and humidity, can also affect the results. Uneven curing can cause variations in the strength of the specimen, leading to inaccurate results.

The testing procedure can also impact the compressive strength test results. Any deviations from the standard procedures can lead to variations in the results. It is important to ensure that the testing apparatus is calibrated and maintained properly to obtain reliable results.

Compressive Strength Test of Concrete

Another important factor to consider is the age of the concrete. The compressive strength of concrete is known to increase with time. Therefore, testing at different ages can produce different test results.

In summary, several factors can contribute to variations in compressive strength test results, including specimen preparation, curing conditions, testing procedures, and age of the concrete. It is essential to follow standard procedures and be aware of these factors to obtain accurate and reliable results.

Conclusion

In conclusion, the compressive strength test of concrete is a crucial step in ensuring the safety and performance of concrete structures. The cube test is a widely accepted method for determining the compressive strength of concrete and can yield accurate and reliable results when conducted correctly.

By conducting the test, construction professionals can evaluate the quality and durability of concrete and make informed decisions regarding its use in projects of all sizes. The test results provide valuable insights into the structural integrity of the concrete, which can be used to optimize project management and ensure that safety standards are met.

Overall, the compressive strength test of concrete has become an essential part of modern construction practices and should be conducted by all construction professionals. By adhering to the appropriate code of practice, using accurate and reliable testing equipment, and following procedures correctly, the compressive strength test of concrete can provide a wealth of information that is crucial to the success of any construction project.

So, one cannot deny the significance of the compressive strength test of concrete, also known as the cube test. It is an invaluable tool for the construction industry, providing vital information about the concrete’s quality and strength. Therefore, it is essential to conduct this test to ensure the safety of the built environment.

For more details and insights into the compressive strength test of concrete and the cube test, stay tuned to our upcoming articles on this topic.

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning

Compressive Strength Test of Concrete