The Compaction Factor Test is a crucial aspect of ensuring the quality and durability of concrete. It is a measure of the workability of concrete, which is essential for ensuring the proper placement and consolidation of concrete during construction. This test is conducted as per the relevant IS CODES and helps to determine the consistency of the concrete mix.

IS 1199 – 1959, ACI 211.3-75 (revised 1987), and BS 1881-103:1993 are some of the relevant IS Codes for the Compaction Factor Test. The principle behind this test is based on the amount of compaction that can be achieved by a standardized amount of concrete in a standardized manner.

This section will provide a comprehensive overview of the Compaction Factor Test, including its aim, relevant IS CODES, principle, significance, advantages, and the test procedure. Read on to learn more about this important test for evaluating concrete mixtures.

Key Takeaways:

- The Compaction Factor Test is vital for ensuring the quality and durability of concrete.

- The test is conducted as per relevant IS CODES and helps to determine the consistency of the concrete mix.

- IS 1199 – 1959, ACI 211.3-75 (revised 1987), and BS 1881-103:1993 are some of the relevant IS Codes for the Compaction Factor Test.

- The principle behind this test is based on the amount of compaction that can be achieved by a standardized amount of concrete in a standardized manner.

- This section will provide a comprehensive overview of the Compaction Factor Test, including its significance, advantages, and the test procedure.

What is the Compaction Factor Test?

The Compaction Factor Test is a standardized test method used to determine the workability of concrete. The test is conducted to measure the ease with which concrete can be compacted and its ability to flow. It is an essential test that helps to ensure the quality and durability of concrete in construction projects.

The Compaction Factor Test is widely used in the concrete industry to determine the water-cement ratio and the correct amount of aggregate required for the desired consistency. It is also used to evaluate the effects of admixtures, such as plasticizers and superplasticizers, on the workability of concrete.

During the test, the concrete is placed in a cone-shaped metal mold and compacted with a steel rod. The mold is lifted, and the concrete is allowed to spread. The compaction factor is then calculated by comparing the weight or bulk density of the compacted concrete to the weight or bulk density of the same amount of concrete without compaction.

The Compaction Factor Test is an essential part of the concrete standardization process. It helps to ensure that all concrete mixtures meet the necessary quality requirements and can withstand the environmental conditions in which they are used.

Importance of the Compaction Factor Test

The Compaction Factor Test is an important criterion for ensuring the quality and durability of concrete. It measures the consistency of fresh concrete, allowing engineers to determine whether the concrete will be workable enough for the specified application. The significance of the Compaction Factor Test lies in its ability to measure the workability of concrete mixtures, which is essential to ensure that the final product meets the strength and durability requirements.

The Compaction Factor Test also contributes to the reduction of variability in concrete uniformity across multiple batches. Enforcing strict quality standards helps to reduce the level of undesirable variation and improve the overall quality of concrete, ultimately contributing to overall cost savings in construction projects.

Furthermore, conducting the Compaction Factor Test provides valuable data on the concrete’s behavior during on-site placement, including its resistance to segregation and bleeding. This information can be used to adjust the concrete mixture to ensure optimal performance in different environmental conditions and to reduce the potential for any defects or failures in the final product.

Therefore, the importance of the Compaction Factor Test lies in its ability to measure and assess the workability of concrete, and contribute to the reduction of variability, improving the overall quality, durability, and longevity of structures.

IS Code for the Compaction Factor Test

IS CODES are crucial in ensuring that the Compaction Factor Test is performed accurately and in compliance with industry standards. The relevant IS CODE for the Compaction Factor Test includes:

| IS CODE | Description |

|---|---|

| IS 1199 – 1959 | Method for the determination of the workability of concrete by the slump test |

| ACI 211.3-75 (revised 1987) | Standard practice for selecting proportions for normal, heavyweight, and mass concrete |

| BS 1881-103:1993 | Method for determination of compacting factor of fresh concrete using a vibrating table |

These CODES outline the recommended test procedure, apparatus, and calculations required for conducting the Compaction Factor Test accurately and efficiently.

Principle of the Compaction Factor Test

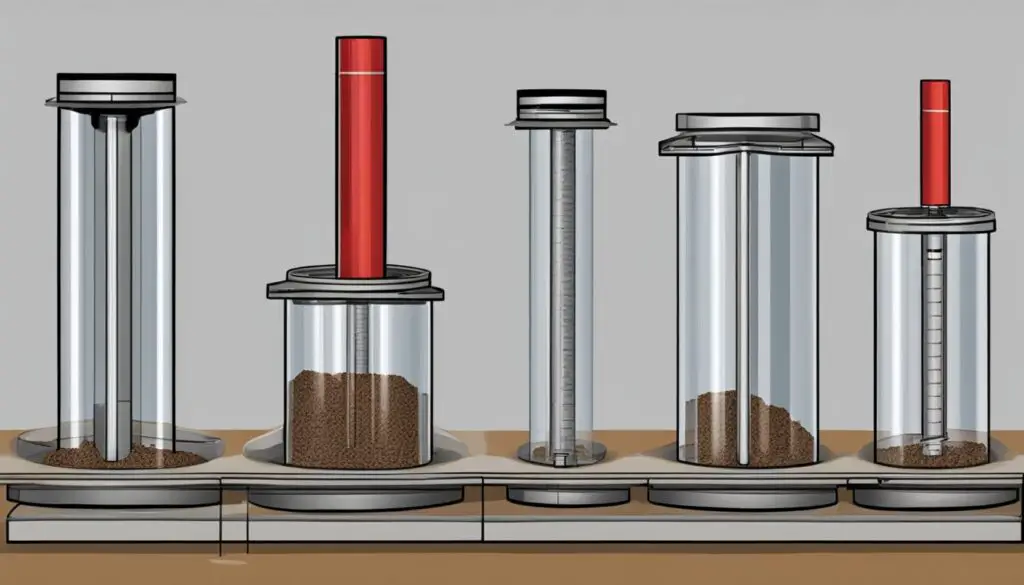

The Compaction Factor Test measures the workability of concrete by calculating the ratio of the weight of partially compacted concrete to the weight of fully compacted concrete. This test follows the principle that the workability of concrete depends on the amount of compaction it undergoes during construction.

During the test, the partially compacted concrete is filled into a standard mold and vibrated using a standard vibrating table just enough to fill the mold uniformly. The diameter of the mold and the height of the concrete are recorded. Afterwards, it is emptied and the mold is refilled with the same concrete, this time fully compacted with the help of a standard compacting bar. The diameter and height of the concrete in the second mold are recorded as well.

The ratio of the height of the partially compacted concrete to that of fully compacted concrete helps to determine the compaction factor value, which indicates the amount of compaction the concrete requires in the field. A high compaction factor value indicates that the concrete is stiff and may need more water to be workable, while a low value indicates that the concrete is too wet and may not be strong enough for construction.

Note: The image above showcases the principle of the Compaction Factor Test by depicting the difference in concrete height between partially compacted and fully compacted concrete.

Advantages of the Compaction Factor Test

The Compaction Factor Test is an important test for determining the workability of concrete mixtures. Here are some advantages of using this test:

- Accuracy: The Compaction Factor Test provides accurate and reliable results, ensuring the correct workability of concrete mixtures.

- Efficiency: The test is quick and easy to perform, allowing for faster production of concrete.

- Cost-effective: Since the test is straightforward, it does not require expensive equipment or specialized expertise, reducing costs significantly.

- Control: The Compaction Factor Test provides concrete producers with the necessary control over the properties of concrete, enabling them to meet the necessary standards and regulations.

- Quality assurance: This test ensures the quality of the concrete produced for various types of construction. The results from the test can be used to regulate batching and facilitate production consistency.

Overall, the Compaction Factor Test is a valuable tool for concrete producers to determine the workability of their mixtures with ease and efficiency, ensuring the quality and reliability of concrete products for a wide range of construction applications.

Theory of the Compaction Factor Test

The Compaction Factor Test is based on the concept of measuring the workability of concrete using the ratio of the weight of partially compacted concrete to the weight of fully compacted concrete. This ratio is commonly referred to as the compaction factor value (CF value).

The theory behind the Compaction Factor Test is straightforward. The test measures the flowability of concrete and considers factors such as the quantity and quality of aggregates, grading of aggregates, water-cement ratio, and temperature. The test is also influenced by aggregate shape, texture, and particle size distribution.

It is essential to understand that the Compaction Factor Test is a unique test that does not measure the same characteristics as the slump test. Although the principle of both tests is to measure workability, the Compaction Factor Test measures the amount of compaction while the slump test measures the degree of deformation. Therefore, the two tests cannot be used interchangeably.

Relationship between Compaction Factor and Slump Value

A significant advantage of the Compaction Factor Test is its close correlation with the slump test results. A graph of the relationship between the compaction factor value and slump value shows a strong correlation between the two, as shown in the following illustration:

As shown in the graph, it is possible to estimate the slump value using the compaction factor value. This relationship is valuable for concrete mix design as it helps to determine the appropriate water-cement ratio and consistency required to achieve a certain slump value or compaction factor value.

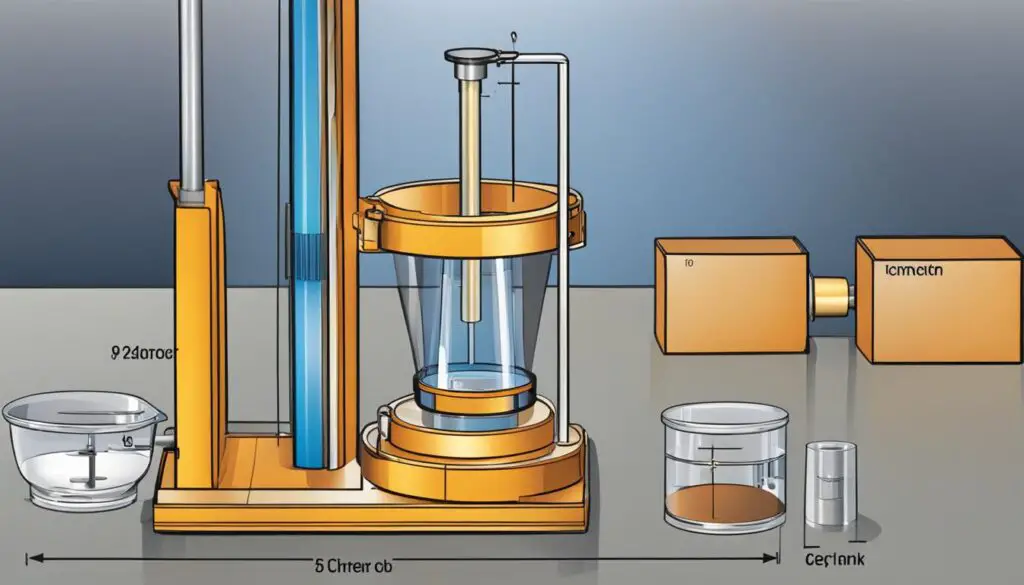

Apparatus Used in the Compaction Factor Test

For conducting the Compaction Factor Test, the following apparatus are required:

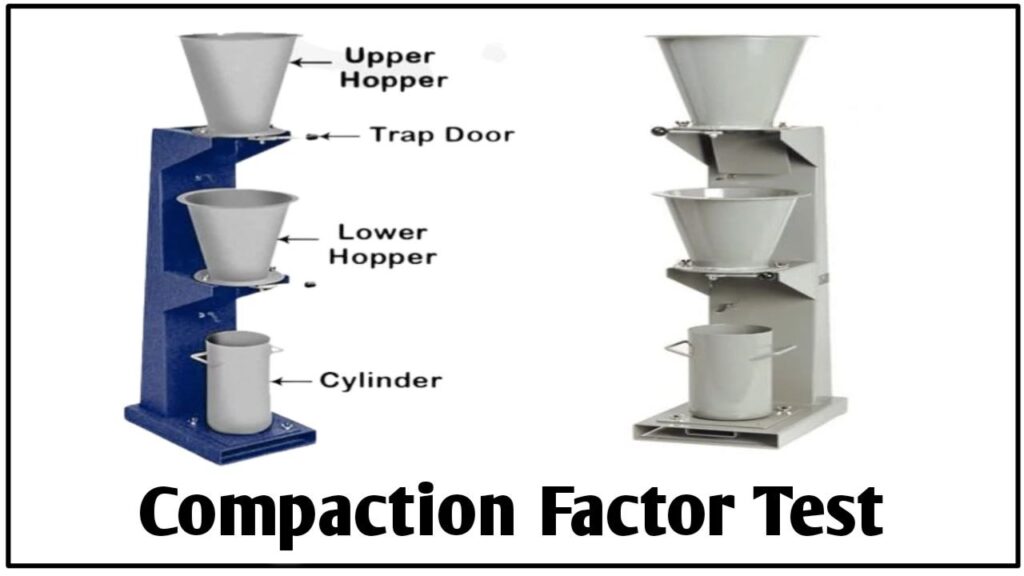

- Compaction factor apparatus: The compaction factor apparatus consists of two hoppers that fit one above the other and a cylindrical metal Mould. The test is performed with the help of a tamping rod of diameter 16mm and a length of 600mm.

- Weighing machine: A digital weighing machine with an accuracy of ±0.1% of the weight of the sample is needed for determining the weight of the concrete sample and aggregates.

- Steel trowel/mechanical vibrator: A steel trowel or a mechanical vibrator with an amplitude of 1 to 2mm and a frequency of 2 to 3 Hz is used to compact the surface of the concrete.

Precautions for the Compaction Factor Test of Concrete

Performing the Compaction Factor Test of concrete requires certain precautions that must be kept in mind to ensure accurate and reliable results. Following these precautions can help prevent errors and ensure that the test results are precise.

Precautions for the Compaction Factor Test:

- Moisture Content: The concrete mix sample must be tested with the correct moisture content to prevent any discrepancies in the results obtained from the Compaction Factor Test.

- Consistency of the Concrete Mixture: The consistency of the concrete mixture must be consistent throughout the testing process.

- Proper Calibration: The Compaction Factor Machine must be calibrated before using it to ensure the accuracy of the Compaction Factor Test results.

- Smooth Surface: The surface of the Compaction Factor Machine needs to be leveled and smooth before placing the concrete mixture sample.

- No Vibration: The Compaction Factor Test should not be performed on a vibrating surface, and the machine should not be vibrated during the test.

It is crucial to follow all necessary precautions and procedures when conducting Compaction Factor Tests of concrete to ensure that the results obtained are accurate, reliable, and meet the required standards.

The procedure of the Compaction Factor Test

The Compaction Factor Test is conducted in the following steps:

- Take the concrete mixture sample and weigh it.

- Set the compaction factor machine to the maximum height and adjust the hopper and bottom plate for a clean start.

- Place the concrete into the hopper in three equal layers, compacting each layer with 25 blows using the bar with the rounded end. This needs to be repeated three times for a total of 75 blows.

- After the final layer of concrete is compacted, level the surface using a steel trowel or vibrating machine.

- Take the weight of the compacted concrete and confirm it is in the range of 7.5 kg/cm2 to 8.0 kg/cm2.

- Calculate the Compaction Factor Value using the formula: Compaction Factor = WP/ WF

where A is the weight of partially compacted concrete, and B is the weight of fully compacted concrete.

In addition to these steps, there are a few points that must be kept in mind while performing the Compaction Factor Test:

- Ensure the hopper and bottom plate are cleaned before starting the test.

- Compact and level each layer of concrete uniformly.

- Take the weight of the compacted concrete accurately.

- Repeat the test twice or thrice to get more accurate results.

- The equipment used for the test must be calibrated periodically to maintain accuracy.

Calculation of the Compaction Factor Test

Calculating the compaction factor value is a crucial part of the Compaction Factor Test, as it helps determine the workability of concrete. The compaction factor value is calculated using the formula:

Compaction factor = (Weight of partially compacted concrete / Weight of the fully compacted concrete) x 100

After performing the test, the weight of the partially compacted concrete is determined by subtracting the weight of the cylindrical metal Mould from the weight of the Mould filled with the partially compacted concrete. The weight of the fully compacted concrete is obtained by adding the weight of the metal Mould, concrete, and any surplus to the weight of the Mould filled with the fully compacted concrete.

Once these values are obtained, the compaction factor value can be calculated using the above formula. This value is used to classify the workability of concrete based on the range it falls under:

| Compaction Factor Value | Workability Classification |

|---|---|

| 0.78-0.83 | Very low workability |

| 0.84-0.87 | Low workability |

| 0.88-0.92 | Medium workability |

| 0.93-0.95 | High workability |

| Above 0.95 | Very high workability |

The above classification table helps in identifying the level of workability of the concrete based on the compaction factor value obtained from the test. It is important to note that the compaction factor value is affected by various factors such as moisture content, aggregate size and shape, and cement content, among others. Therefore, caution must be exercised while interpreting the test results.

Graph Showing the Relationship Between Compaction Factor Value and Slump Value

One of the key benefits of the Compaction Factor Test is its ability to determine the workability of concrete mixtures. A graph that illustrates the relationship between the compaction factor value and slump value can help to better understand this correlation. The graph below shows the relationship between the compaction factor value and the slump value of concrete mixtures.

There is a direct relationship between the compaction factor value and the slump value of concrete mixtures. The higher the compaction factor value, the lower the slump value, indicating low workability of the concrete mixture. Conversely, a lower compaction factor value corresponds to a higher slump value, suggesting a higher workability.

Test Results and Interpretation

After conducting the Compaction Factor Test, the results need to be interpreted to evaluate the quality of the concrete. The compaction factor value obtained from the test indicates the workability of the concrete mixture, and it is an essential parameter used for designing concrete mixes.

Generally, a low compaction factor value indicates a poorly workable concrete mix, while a high compaction factor value indicates good workability. However, the ideal compaction factor value for a particular concrete mix depends on various factors, such as the presence of admixtures, cement content, and aggregate grading.

The interpretation of the test results requires a thorough understanding of the mix design and the properties of the materials used. By analyzing the results obtained from the Compaction Factor Test, engineers can make adjustments to the mix design to enhance its performance and ensure the desired strength and durability of the concrete.

It is crucial to compare the test results with the standard values specified in relevant codes and standards, such as the IS Code for the Compaction Factor Test. Any significant deviation from the standard values could indicate a problem in the concrete mix or the testing procedure.

The image above shows an example of how to interpret the test results obtained from the Compaction Factor Test. As seen from the graph, there is a clear relationship between the compaction factor value and the slump value of the concrete mix. By correlating these two parameters, engineers can evaluate the workability and consistency of the concrete batch.

Future Developments and Advancements in the Compaction Factor Test

The Compaction Factor Test has been a vital tool in the concrete industry for many years, contributing to the quality and durability of concrete throughout various construction projects. With the rapid advancements in technology and materials, it is natural to consider what the future holds for the Compaction Factor Test.

One possible area of development is the integration of artificial intelligence (AI) and machine learning algorithms. These could help in accurately predicting the performance and workability of concrete mixtures with a higher degree of accuracy, thus reducing the number of physical tests required.

Another exciting prospect is the use of advanced sensors and imaging techniques in the Compaction Factor Test. These sensors could detect minute changes in the concrete mixture and provide highly precise and detailed data on the workability and other parameters of the concrete under test.

The continued development of these technologies will not only enhance the accuracy of the Compaction Factor Test but also contribute to the sustainability and resource efficiency of the construction industry. Therefore, the Compaction Factor Test is likely to remain a critical tool for ensuring the quality and durability of concrete for years to come.

In conclusion, the synergy between the construction industry and technology will bring significant advancements in the Compaction Factor Test. The integration of AI and advanced sensors can help optimize concrete mixtures while reducing wastage and ensuring the safety, durability, and quality of concrete structures.

Conclusion

Overall, the Compaction Factor Test is an essential tool for assessing the workability of concrete mixtures and ensuring their quality and durability. By measuring the compaction factor value and its correlation to slump value, concrete producers can make informed decisions about the suitability of their mixtures for construction applications.

Although there are a few precautions to take when conducting the test, its advantages are numerous, which is why the Compaction Factor Test is widely used and recognized by various concrete standards. Additionally, as the concrete industry continues to evolve, future developments and advancements in the Compaction Factor Test may further improve its accuracy and applicability.

In summary, understanding the Compaction Factor Test and how it fits into the concrete production process is crucial for maintaining high-quality construction standards. So, whether you’re a concrete producer or a construction professional, it’s worth familiarizing yourself with this important test and its applications.

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning

Also, Read,