All About AAC Block – An Ultimate Guide

What is AAC Block

AAC stands for Autoclaved Aerated Concrete, a type of building material that is lightweight and precast. It’s made from natural ingredients such as cement, lime, sand, water, and a small amount of aluminum powder.

The aluminum powder reacts with the other ingredients to produce tiny air pockets, which give the AAC block its lightweight and highly insulating properties. Once poured into molds, it is cured under high pressure and temperature in an autoclave, which provides strength and durability.

AAC blocks are a popular choice for construction projects due to their lightweight nature, ease of installation, energy efficiency, excellent thermal insulation, and soundproofing properties. They are also fire-resistant and have a high load-bearing capacity, making them a reliable choice for building walls, floors, and roofs.

When AAC block was first invented?

AAC (Autoclaved Aerated Concrete) blocks are a relatively new building material that has gained popularity in recent years due to their unique properties, which make them an excellent alternative to traditional concrete blocks. It has been used in construction since the early 20th century. The invention of AAC blocks is credited to a Swedish architect and inventor named Johan Axel Eriksson, who developed the material in the early 1920s.

The team was inspired by the properties of naturally occurring pumice stone, which is lightweight and porous. Their goal was to create a material that combined the strength and durability of concrete with the insulating properties and workability of pumice. After several years of experimentation, Eriksson and his team developed a method to create lightweight and aerated concrete by adding an expansion agent, which resulted in the formation of small air pockets within the material.

Eriksson was interested in finding a building material that was both lightweight and strong, and that would also provide good insulation properties. He began experimenting with different mixtures of cement, lime, water, and sand, along with various additives such as aluminum powder and gypsum.

In 1924, Eriksson patented a new type of building material that he called “aerated concrete,” which was made by combining cement, lime, and water with a small amount of aluminum powder. This mixture was then poured into molds and allowed to cure for several hours before being steam-cured in an autoclave.

The aluminum powder in the mixture reacted with the lime and water to produce hydrogen gas, which expanded the mixture and created a large number of small, uniformly distributed air pockets throughout the material. This gave the material its lightweight and insulating properties while also providing it with good strength and durability.

Eriksson’s invention quickly gained popularity in Sweden, and AAC blocks were used in a variety of construction projects, including residential and commercial buildings, bridges, and even ships. The material was particularly popular in the Scandinavian countries, where the harsh climate and high cost of energy made it essential to have buildings with good insulation properties.

Over the years, the process for making AAC blocks has been refined and improved, with the addition of new additives and the development of more efficient production methods. Today, AAC blocks are made using a mixture of cement, lime, fly ash or sand, and water, along with small amounts of additives such as aluminum powder, silica fume, and gypsum.

The manufacturing process for AAC blocks involves several steps. First, the raw materials are mixed together in a mixer to form a slurry. This slurry is then poured into molds, which are then placed in an autoclave for several hours of steam-curing.

During the steam-curing process, the aluminum powder reacts with the lime and water to produce hydrogen gas, which expands the mixture and creates characteristic air pockets. The autoclave provides the necessary heat and pressure to cure the blocks and ensure that they are strong and durable.

After the blocks are cured, they are removed from the molds and stacked in a warehouse for several weeks to allow them to dry and cure further. Once they are dry, they are ready to be used in construction projects.

AAC blocks have many advantages over traditional concrete blocks. They are lightweight, which makes them easy to handle and transport, and they have excellent insulation properties, which can help reduce heating and cooling costs in buildings. They are also strong and durable, with good resistance to fire, water, and pests.

In addition to their practical advantages, AAC blocks are also environmentally friendly. They are made from natural materials and do not produce any toxic byproducts during the manufacturing process. They are also recyclable and can be crushed and reused as raw material for new blocks.

Today, AAC blocks are used in construction projects around the world and are known for their strength, durability, and environmental friendliness.

Manufacturing Process

The manufacturing process of AAC blocks consists of the following steps:

i). Raw material preparation

The raw materials (sand, cement, lime, and water) are proportioned and mixed together.

ii). Expansion agent addition

Aluminum powder is added to the mixture, which reacts with the other components to produce hydrogen gas. This process causes the mixture to expand and create characteristic air pockets.

iii). Molding and Cutting

The aerated concrete mixture is poured into molds and allowed to be partially set. Once it reaches the desired consistency, it is cut into blocks or panels.

iv). Curing

The cut blocks are then placed in an autoclave (a high-pressure steam chamber) and subjected to high-pressure steam at temperatures around 180-210°C (356-410°F) for 12 to 16 hours. This process strengthens the blocks and enhances their durability.

v). Packaging and storage

After the autoclaving process, the AAC blocks are removed, allowed to cool, and then packaged for storage or transportation.

Future of AAC blocks

The future of Autoclaved Aerated Concrete (AAC) blocks appears promising due to the growing demand for environmentally friendly and energy-efficient construction materials. Some trends and developments expected to shape the future of AAC blocks include:

i). Increased Adoption

As awareness about the benefits of AAC blocks grows, more builders, architects, and developers are expected to adopt these lightweight, energy-efficient, and environmentally friendly materials in their construction projects. This adoption will likely be accelerated by favorable government policies and incentives promoting green construction.

ii). Technological Advancements

As the industry matures, we can expect further innovations in the manufacturing process, leading to improved performance, higher quality, and potentially lower production costs. This can make AAC blocks even more attractive to the construction industry.

iii). Customization And Prefabrication

The future may see an increase in customized AAC blocks designed for specific applications and prefabricated AAC panels that can be easily assembled on-site. This will help reduce construction time, lower labor costs, and improve overall project efficiency.

iv). Focus On Sustainability

As the global focus on sustainability intensifies, the demand for eco-friendly building materials like AAC blocks will grow. This will likely lead to the development of even more sustainable AAC blocks with improved thermal insulation and reduced environmental impact.

v). Integration with Smart Technology

The construction industry is gradually integrating smart technology to improve the efficiency and performance of buildings. In the future, we may see AAC blocks incorporating sensors and other smart technologies to monitor and optimize a building’s performance.

vi). Global Expansion

Although AAC blocks are already widely used in Europe and parts of Asia, there is still significant potential for growth in other markets such as North America, Africa, and South America. Increased awareness of AAC blocks’ benefits and favorable government policies may lead to greater adoption in these regions.

In summary, the future of AAC blocks looks bright due to their numerous advantages and the growing global focus on sustainable construction practices. Technological advancements, increased adoption, and integration with smart technology are some of the trends that will likely shape the future of this industry.

Thank you for taking the time to read this educational blog post about the ALL About AAC Block. We hope that you found it informative and engaging. If you have any questions or comments, please feel free to leave comments in the comment section below. Don’t forget to check out our other educational posts on myengineeringsupport.com for more learning opportunities!

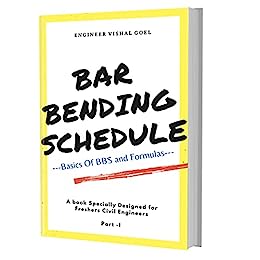

Bar Bending Schedule (BBS) Basics Part -1

This Ebook is specially designed for Freshers Civil Engineers. Recommended for Quantity Surveyors & Billing Engineers. Here You Can Learn All Basic Concepts & Formulas for Bar Bending schedules (BBS).

I hope this information can be useful for you guys.

If you like this article then please share it with your friends & also like our Facebook Page and join our Telegram Channel.

If you want a PDF copy of this, Do let’s know by commenting & you can message us on our Instagram & telegram channel, or you can download it from the top right-hand corner of this post.

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning

Also, Read,

AAC Blocks Manufacturing Process – An Ultimate Guide

How To Check The Quality of AAC Block

28 Important Comparison between WPC and PVC Wall Panel

MDF VS Particle Board – 15 Important Differences

Flush Door vs Wooden Panel Door

Related Video

ALL About AAC Block

Magnolia Finley

This is a great blog and i want to visit this every day of the week .