Bar Bending Schedule Basics (BBS)

In Bar Bending Schedule Basics, Here I’ll cover the following topics…

What is Bar Bending Schedule?

Importance of Bar Bending Schedule?

What advantages of Bar Bending Schedule?

Why Steel is used As Reinforcement Bar?

Size & Unit Weight of Bars.

Bend Deduction of bars & values.

For 180 Degree Bend.

Clear Cover & Effective Cover.

Values of Clear Cover.

Standard Codes Used For BBS.

Symbols & Representation in BBS.

Cutting Length of Bars.

Cutting Length of Crank Bar.

Hook.

Cutting Length Of Rectangular Stirrups.

Cutting Length Of Triangular Stirrups.

Cutting Length Of Circular Stirrups.

Cutting Length of Diamond Stirrups.

Cutting Length of Spiral or Helix Stirrup.

Cutting Length of Chair bar.

What is Bar Bending Schedule?

Bar bending is the process of cutting & Bending reinforcement bars into the required shape.

Important Of Bar Bending Schedule

Location & Marking of Bar

Type of Bar

Size of Bar

Cutting the length of the bar

Number of Bar

Bending details of Bar

Total Quantity

Advantages of Bar Bending Schedule

Cutting length & bending of reinforcement can be done by Bar Bending Schedule.

B.B.S avoids wastage of reinforcement& thus saves the project cost.

It provides a better estimation of reinforcement steel requirements for each & every structure member.

B.B.S. is very much useful during the auditing of reinforcement & provides checks for theft & pilferage.

It enables easy & fast preparation of bills of construction work for clients & contractors.

Why Steel is used As Reinforcement Bar?

Coefficient of thermal expansion characteristics similar to concrete.

Good strength for the economic design of R.C.C. structure.

Good gripping or good bonding with concrete.

Good resistance against corrosion for higher durability.

Good bed ability for providing required shape.

Size & Unit Weight of Bars

Dia. Of Bar

8mm

Unit Weight of Bar (D2/162) – (8×8)/162 = 0.395 kg/m.

10mm

(10×10)/162 = 0.617 kg/m.

12mm

(12×12)/162 = 0.889 kg/m.

16mm

(16 x16)/162 = 1.580 kg/m.

20mm

(20×20)/162 = 2.470 kg/m.

25mm

(25×25)/162 = 3.858 kg/m.

32mm

(32×32)/162 = 6.320 kg/m.

Bend Deduction of bars & values

Bend increases the length of bars. So we need a lesser length than we see in the drawing. So, the Cutting length is taken lesser than the required length.

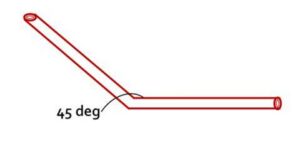

For 45 degree Bend

Always take – 1d

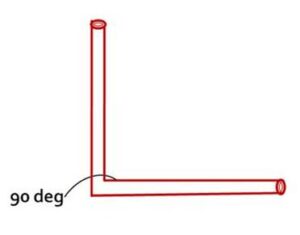

For 90-degree Bend

Always take – 2d

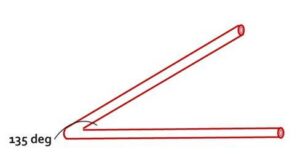

For 135-degree Bend

Always take – 3d

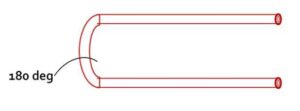

For 180-degree Bend

Always take – 4 d

Standard Length of Bar – 12 meters or 40 feet.

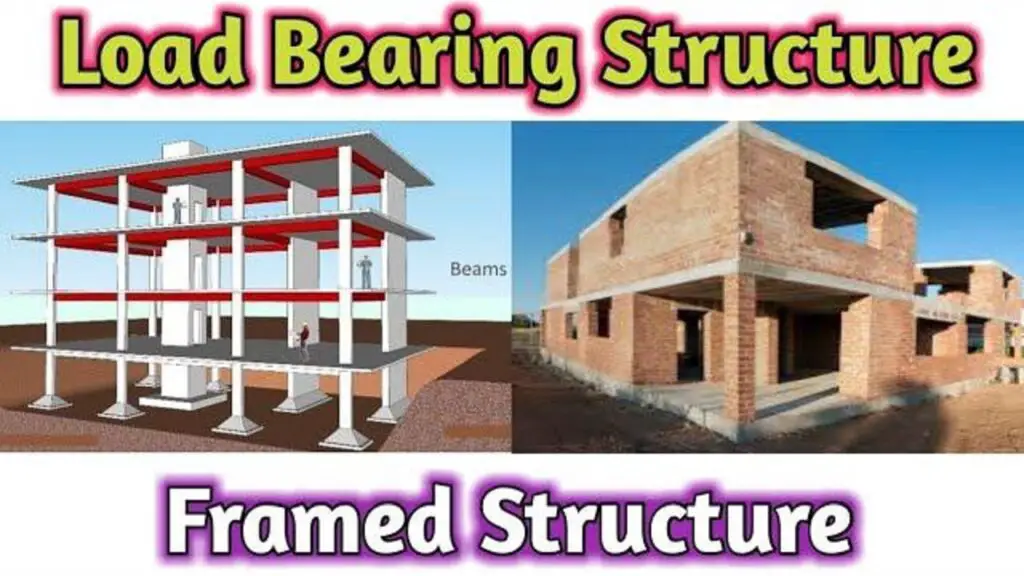

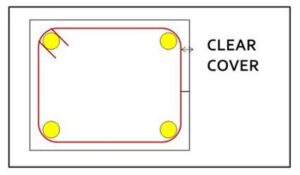

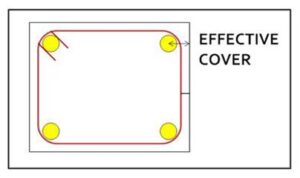

Clear Cover & Effective Cover

The cover is the thickness of concrete measured from the nearest outer surface of reinforcement. The cover is mainly provided to protect the reinforcement bars. In RCC structure reinforcement is provided in concrete up to a specific distance from the face of the member.

Clear Cover

The clear cover is the distance between the outer surface of the concrete to the nearest surface of the reinforcing bar.

Effective Cover

The effective cover is the distance measured from the face of the member to the center of the area(centroid) of the main reinforcement. This is the dimension mostly used for design calculation.

Effective cover = Clear cover + Dia of stirrups/ links + 0.5 x Dia of the main reinforcement bar.

Values of Clear Cover

FOOTING – 50mm

COLUMN – 40mm

BEAM – 25mm

SLAB – 20mm

STAIRCASE – 15mm

CHAJJA – 15mm

PILE – 60mm

PILE CAP – 60mm

IS: 456-2000 Plain & Reinforced Concrete

IS 2502-1963 Code of Practice for bending & fixing?

IS: 5525-1969 Detailing of reinforcement in RCC work.

SP 34-1987 Concrete Reinforcement Detailing.

Symbols & Representation in BBS

Symbols Representation

ϴ Plain Round Bar.

□ Plain Square Bar.

# Deformed Bar.

@ Center to center spacing.

Cutting Length of Bars

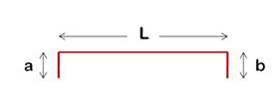

The shape of the Bar Cutting Length of the Bar

CL – a + L + b – bend deduction Bend – deduction – 2 x 2d (90*).

CL – a + L + b – bend deduction Bend – deduction – 2 x 2d (90*).

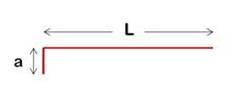

CL – a + L – bend deduction – 1 x 2d (90*).

CL – a + L – bend deduction – 1 x 2d (90*).

CL – L + (2 x Hook Length) Hook Length = 10D

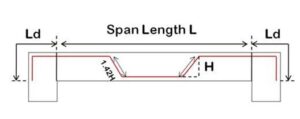

Cutting Length of Crank Bar

Crank length – 0.42d.

Cutting Length – Ld + Span Length (L) + { 0.42H x 2} + Ld – Bend

Deduction (2 x 90* + 4 x 45*).

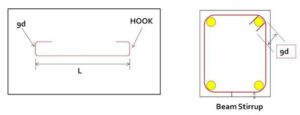

HOOK Cutting Length

Length of hook = 9d or 10d, (where d is the diameter of the bar)

Length of bar = L + 9d + 9d meter.

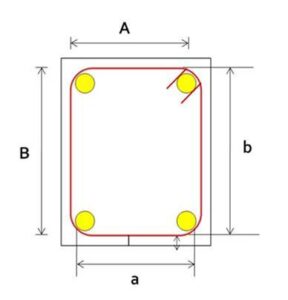

Cutting Length Of Rectangular Stirrups

Cutting Length Of Rectangular Stirrups – (a x 2) + (b x 2) + Hook Length

Where, a = A – (2 x clear cover) – d

a = B – (2 x clear cover) – d

Hook Length = 2 x 10D

Length of hook = 9d or 10d, (where d is the diameter of the bar)

Length of bar = L + 9d + 9d meter.

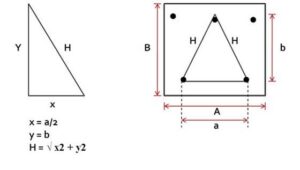

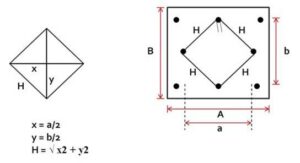

Cutting Length Of Triangular Stirrups

Cutting Length Of triangular Stirrups – (H x 2) + a + Hook Length Where, H = (x2 + y2)⅟2 Where,X = a/2 & Y = b a = A – (2 x clear cover) – d

b = B – (2 x clear cover) – d

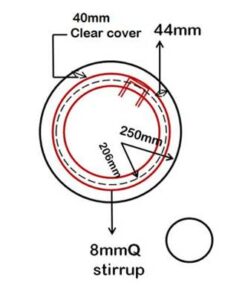

Cutting Length Of Circular Stirrups

Cutting Length of Circular Stirrups = (Pi x d) + Hook length Where d = D – (2 x clear cover) – Dia of the bar. Cutting Length of Diamond Stirrups

Cutting Length Of Diamond Stirrups

Cutting length of diamond stirrups = (H x 4) + Hook Length

Where, H = (x2 + y2)

Where, x = a/2 & y = b/2.

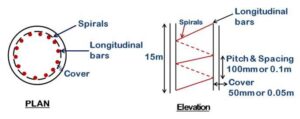

Cutting the Length of Spiral or Helix Stirrups

Length of Helix/Spiral Bar = n√ c2 + p2

So, first, we should find out the value of ‘n’ & ‘c’.

No. of Pitches (n) = H/p+1

Where, Length of pile cage= H

Pitch or spacing of spiral = P

Circumstances (C) = x d

Where,

Dia of spiral Ring (d) = D – (2 x cc) – Dia of the bar.

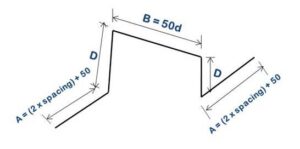

Cutting Length of Chair bar

Cutting length of chair bar = 2A + 2D + B Where, A = (2 x spacing) + 50 B = 50d

D = Footing height – [{ upper + lower cc} + ( Upper side main + dist bar dia + lower side main bar dia)]

Bar Bending Schedule Some Basic Formulas

Spacing:- Distance between two reinforcement bars.

Number of Bars – (Span/spacing) + 1

Number of Stirrups – (Actual length of column/beam/spacing) +1 Overlapping of Bars

For Compression Members (Column) Overlapping should be taken as 40D.

For Tension Members (Beam) Overlapping should be taken as 50D.

For Both, we can take 50D.

Neck column to footing overlapping should be taken as 16D.

Column to Column overlapping 50D.

D – Slab or beam thickness – top & bottom cover.

Length of Extra Bar – L/4.

Total Length of Bars – Length of bars x no. of bars.

Total weight of bars – Total length x weight per meter kg.

Thank you for taking the time to read this educational blog post about the Bar Bending Schedule. We hope that you found it informative and engaging. If you have any questions or comments, please feel free to leave comments in the comment section below. Don’t forget to check out our other educational posts on myengineeringsupport.com for more learning opportunities!

Bar Bending Schedule (BBS) Basics Part -1

This Ebook is specially designed for Freshers Civil Engineers. Recommended for Quantity Surveyors & Billing Engineers. Here You Can Learn All Basic Concepts & Formulas for Bar Bending schedules (BBS).

I hope this information can be useful for you guys.

If you like this article then please share it with your friends & also like our Facebook Page and join our Telegram Channel.

If you want a PDF copy of this, Do let’s know by commenting & you can message us on our Instagram & telegram channel, or you can download it from the top right-hand corner of this post.

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning

Also, Read,

28 Important Comparison between WPC and PVC Wall Panel

MDF VS Particle Board – 15 Important Differences

Flush Door vs Wooden Panel Door

UPVC vs Aluminium vs Wooden Windows

Related Video-